Elasto Bearings

INTRODUCTION

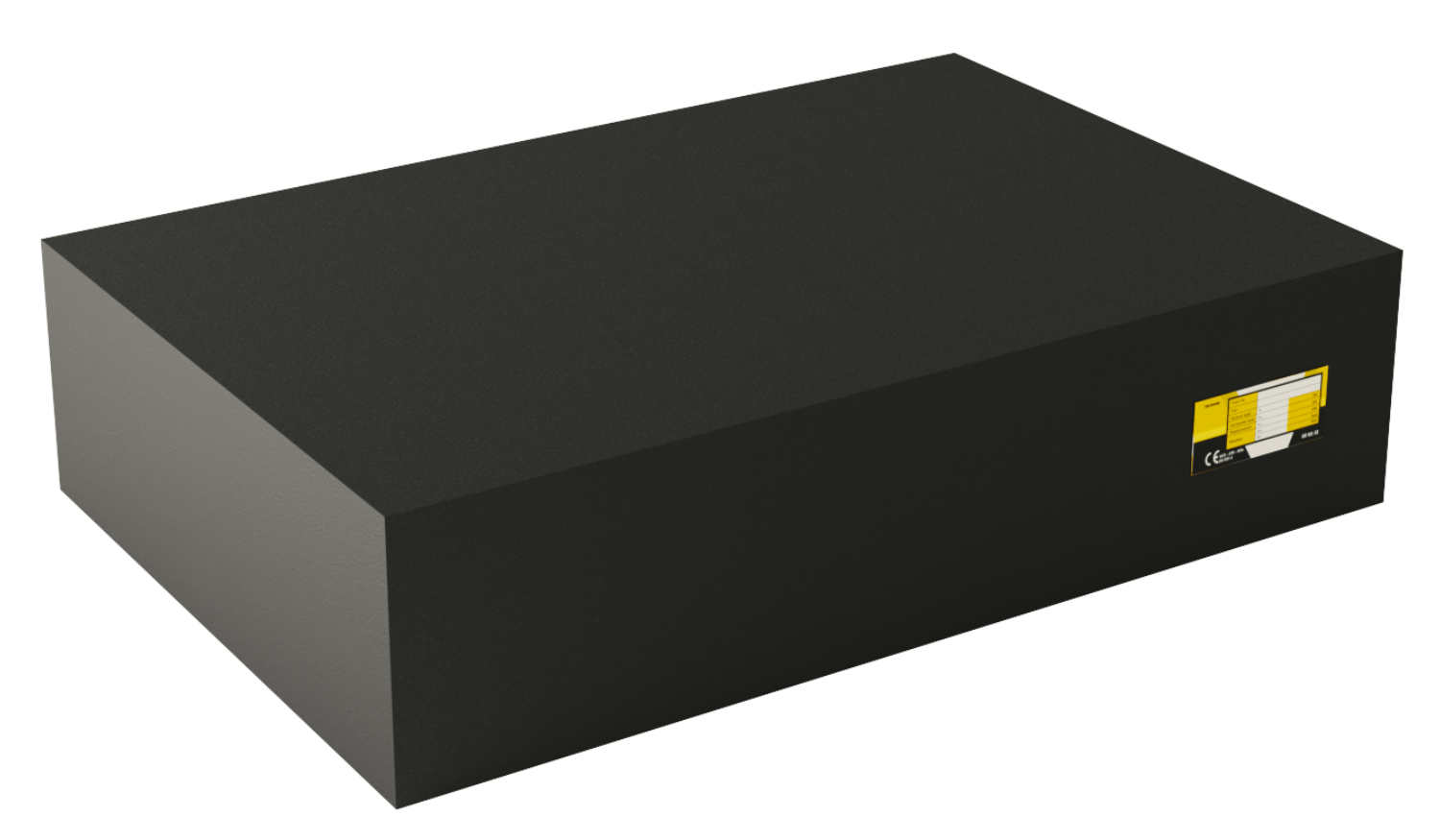

Elasto Bearings

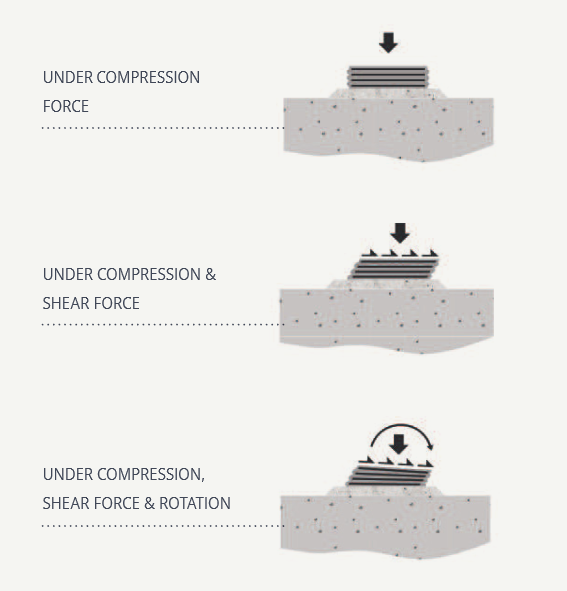

ATAYA’s Elasto-Bearings: Engineered for Bridge Flexibility Bridge movement is inevitable. Thermal changes, wind, and traffic all cause bridges to shift and settle.

ATAYA’s Elasto-Bearings are the answer, engineered from high performance elastomeric materials to absorb these movements and protect the bridge structure.

These versatile bearings come in various configurations that comply with the EN 1337-3 standard.

This ensures you get the perfect solution for your bridge’s specific needs, whether it requires handling horizontal translation, accommodating rotation, or both.

Elastomeric Expansion Joint

(Neoprenejoint)

WHY ELASTO BEARINGS ARE GOOD PRODUCTS?

SIZE

MODERATE COST

VIBRATIONS ABSORPTION

STABILITY

EASY INSTALLATION

DURABILITY

ELASTOmer

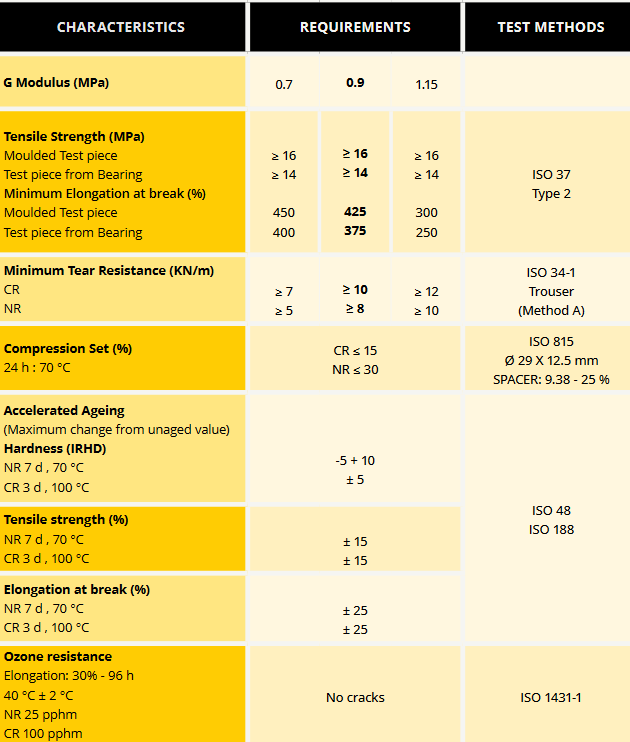

The Elastomer used in the manufacturing of Elastomeric – Bearings should be specified in the project documentation as either natural rubber (NR) or chloroprene rubber (CR) as the raw polymer.

Natural rubber (NR) bearings can be protected by cover of polychloroprene (CR).

The standard design is suitable for operation temperatures between -40°C and +50°C and correlates with the shear modulus class G=0.90 ±0.15 N/mm2 in accordance with EN 1337-3.

Shear modulus (G) can be obtained with other values if specified by the structure designer.

Steel

The Inner Reinforcing plates used in Elasto Bearings are S 235 in accordance with EN 10025.

Their minimum thickness of the inner plates shall be 2 mm. The Outer Reinforcing plates (for Elasto C) are S 235.

For Elasto C with internal layers less than or equal to 8 mm thick, the minimum thickness of the outer plates shall be 15 mm. For Elasto C with internal layers bigger than 8 mm thick, the minimum thickness of the outer plates shall be 18 mm.

Type of ELASTO BEARINGS

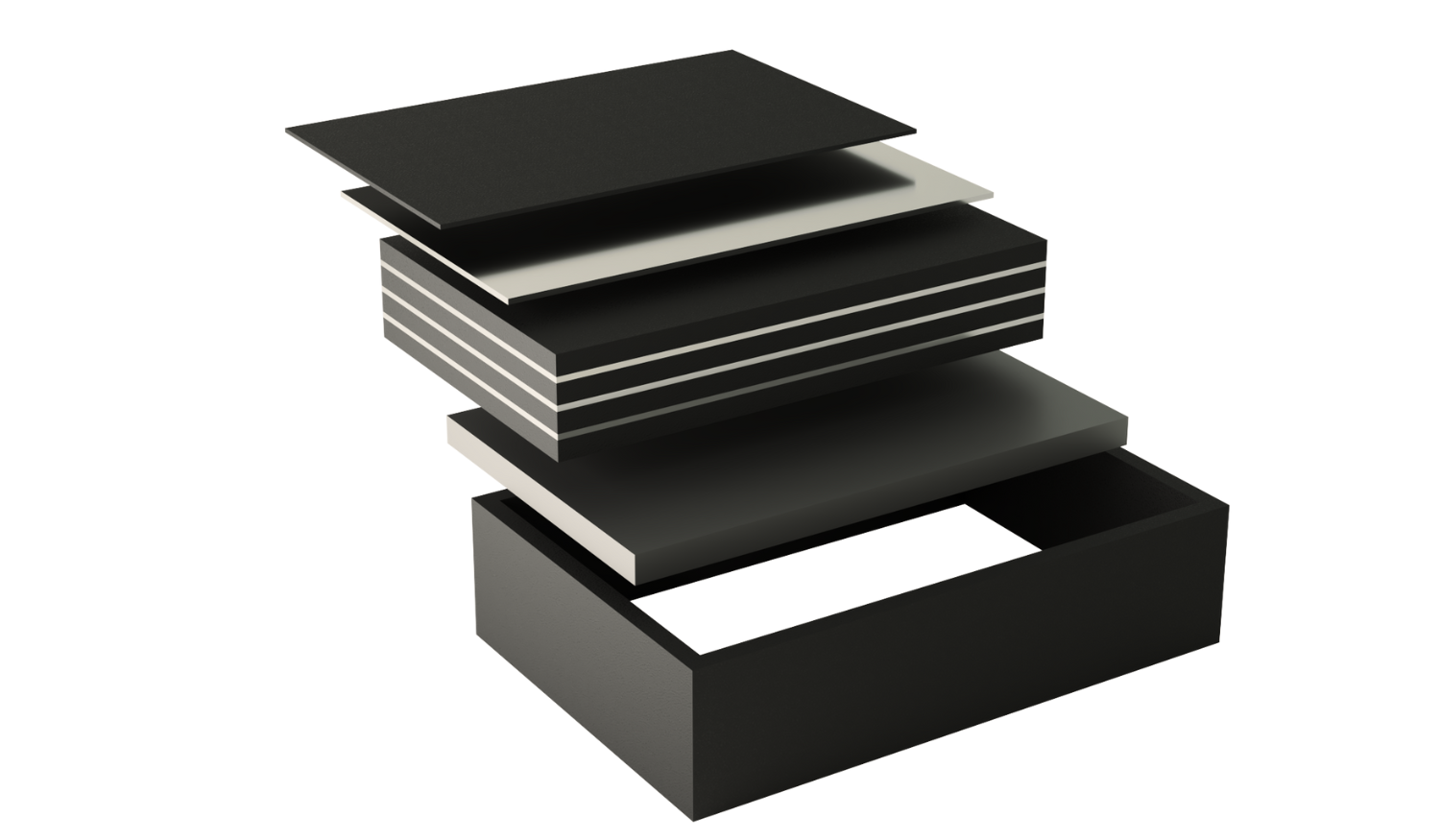

Elasto A

This type of bearing, fully covered with elastomer, comprising only one steel reinforcing plate.

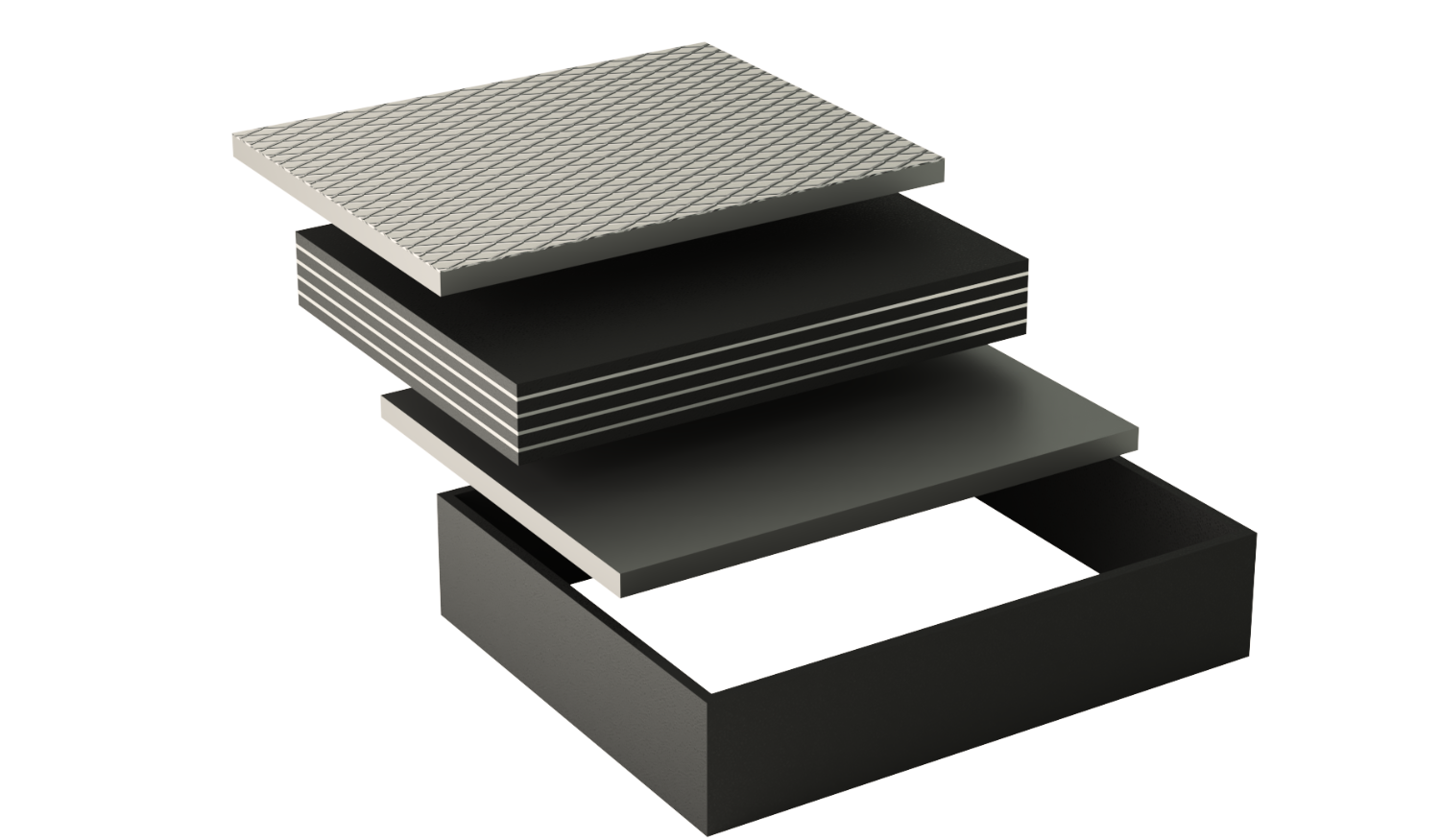

Elasto B

This type of bearing, fully covered with elastomer, comprising more than one reinforcing plate.

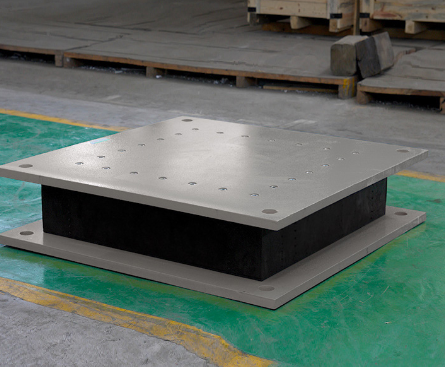

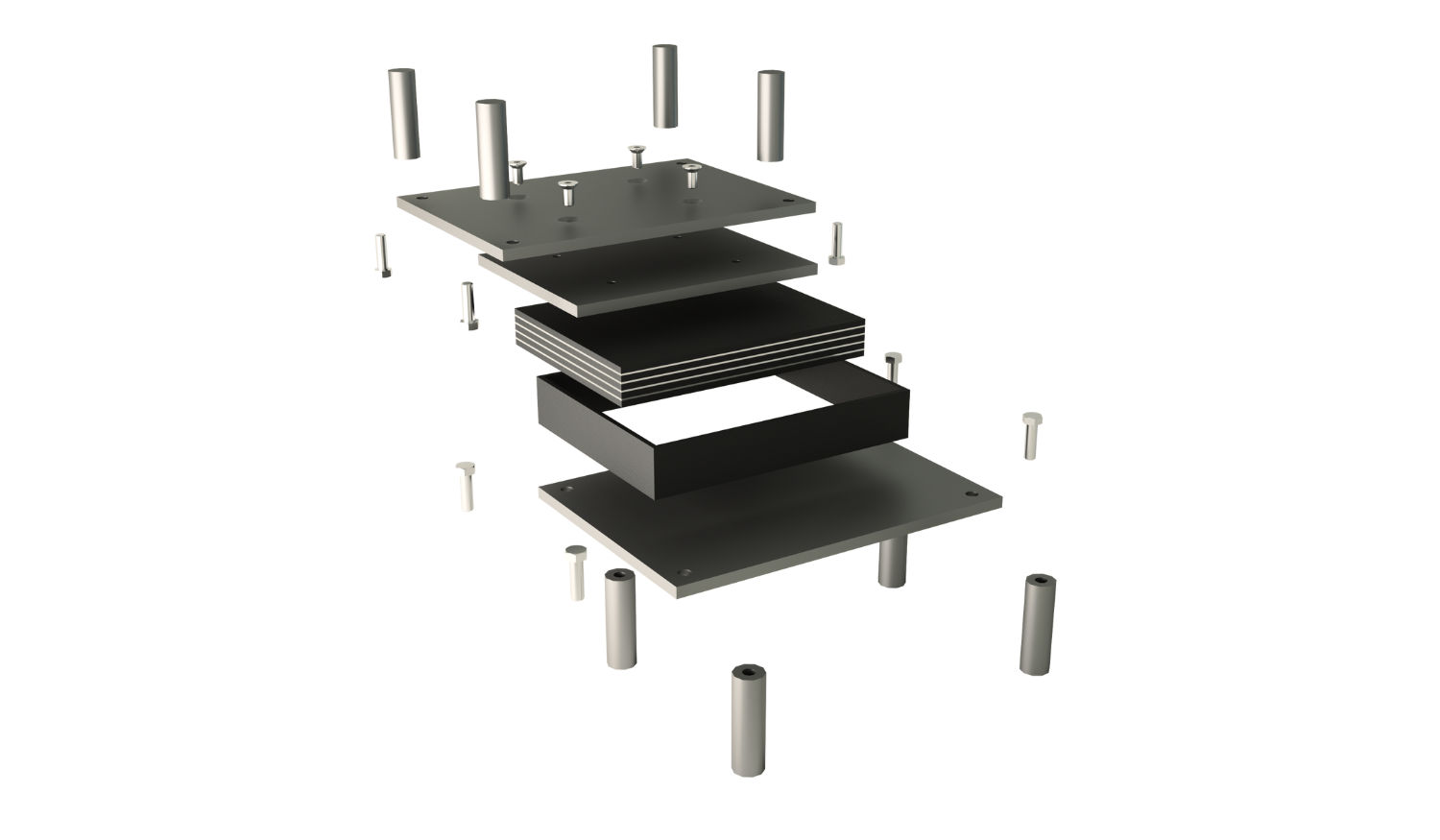

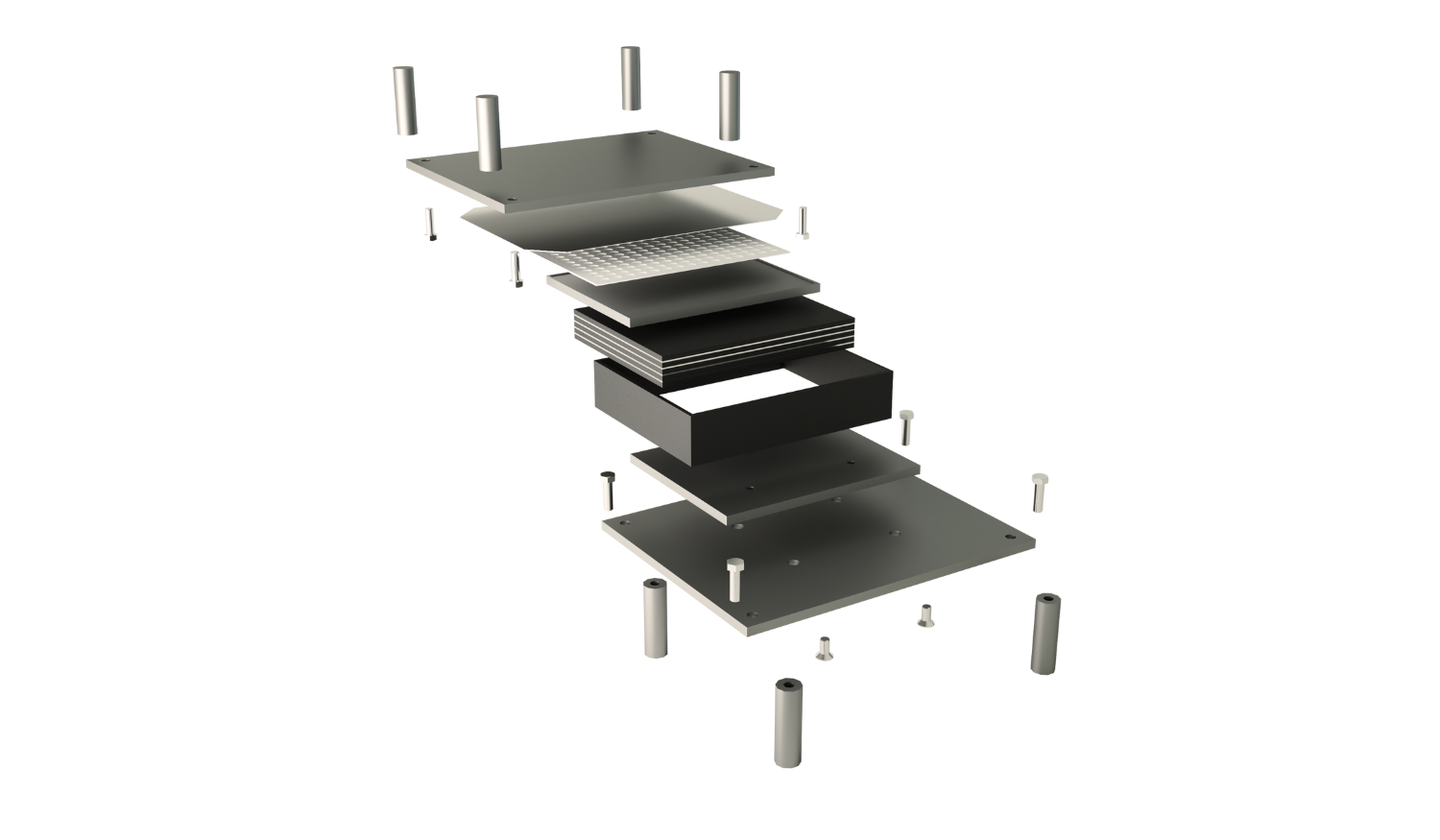

Elasto C with anchors

This type of bearing also features external steel plates, vulcanized into its upper and lower surfaces; allows external connections to steel plates with shear dowels or bolts. The bearing can be replaced simply by minimum lifting of the structure, since there are no embedded anchoring elements.

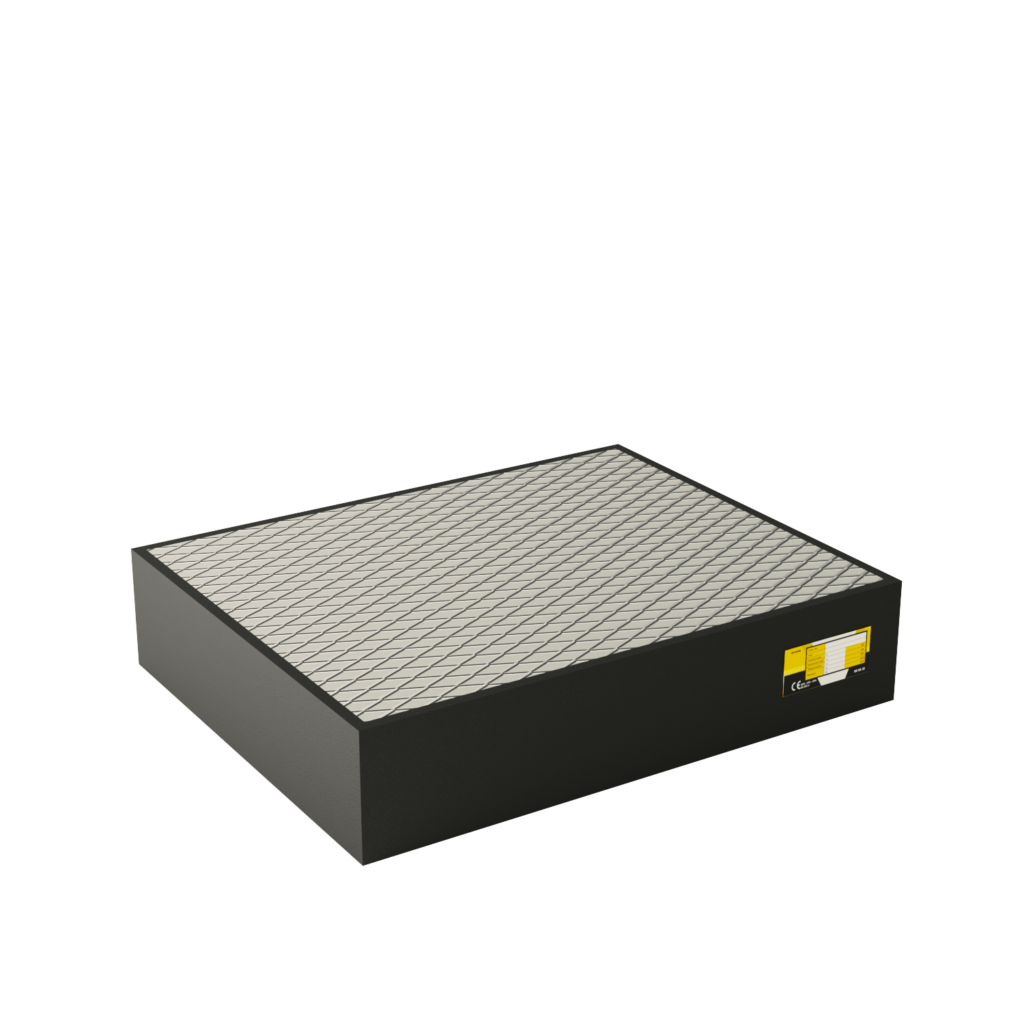

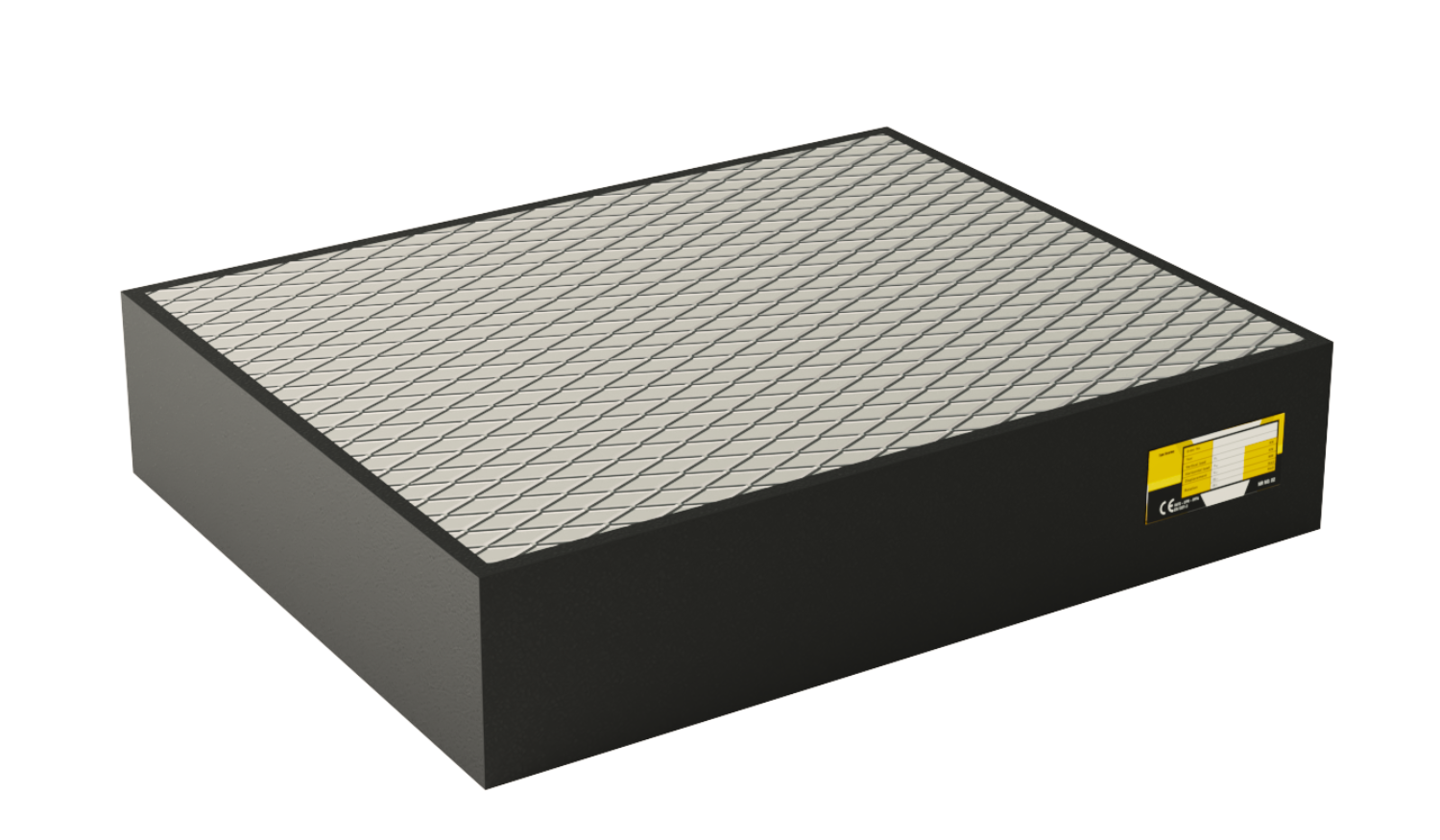

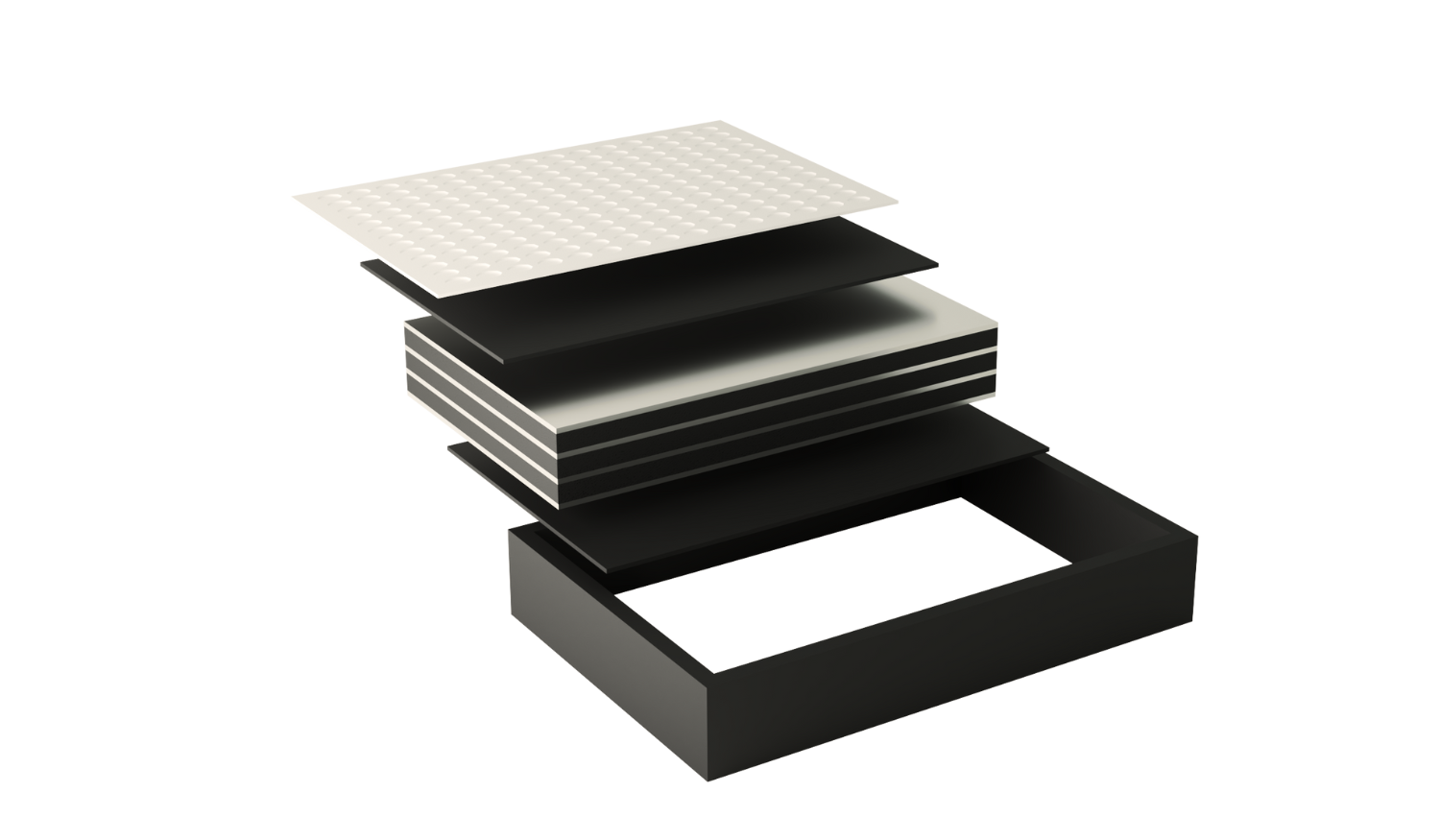

Elasto C without anchors

This type of bearing are same as type C but with Checker plate instead of flat steel plate on the surface, enabling installation directly onto a mortar bed.

Elasto B/C

These types of bearings are combination of types B and C, with only one side featuring an external steel plate.

Elasto D

This type of bearing is same as type B but with PTFE plate

vulcanized into its upper surface.

Elasto E

This type of bearing is same as type C with PTFE plate recessed

into its outer steel plate.

Elasto F

This type of bearing is made only of rubber without any internal

steel plate (not reinforced). They are used when vertical load and horizontal displacement are small.

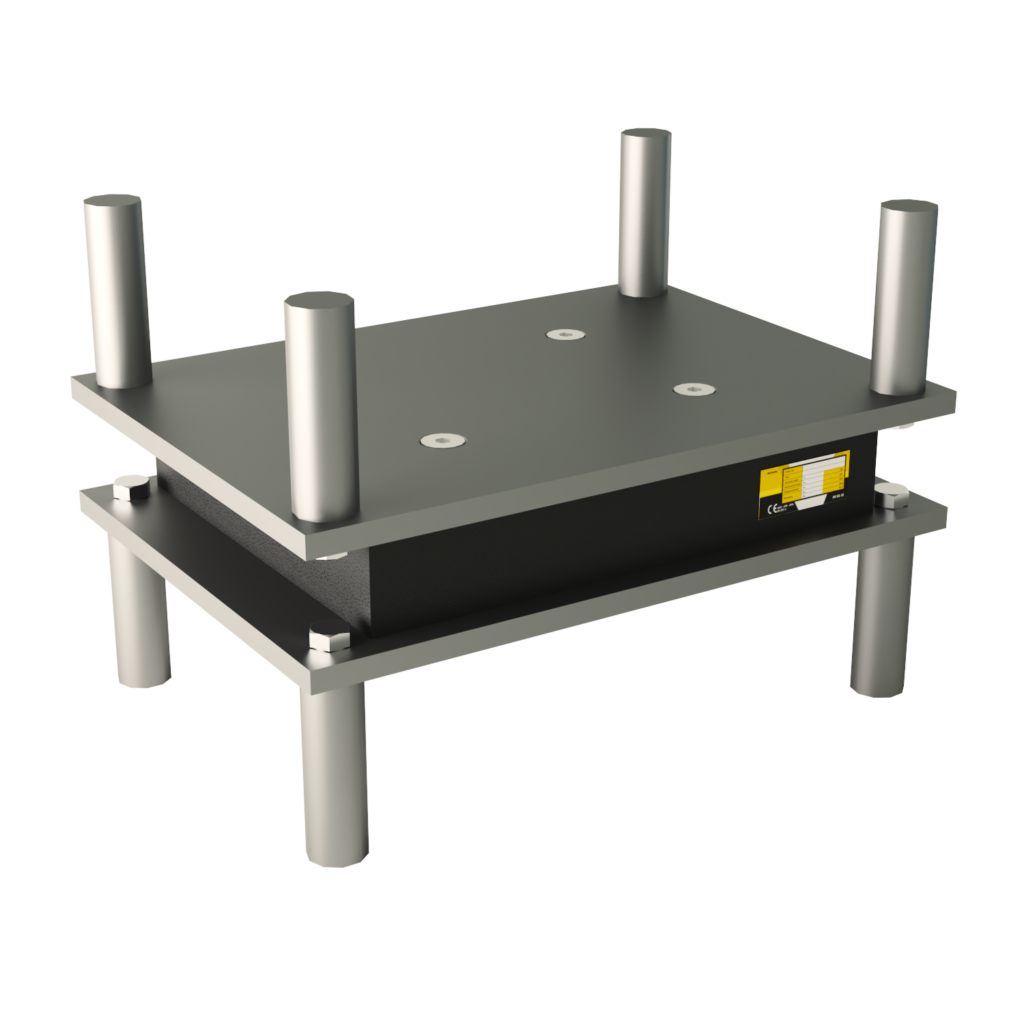

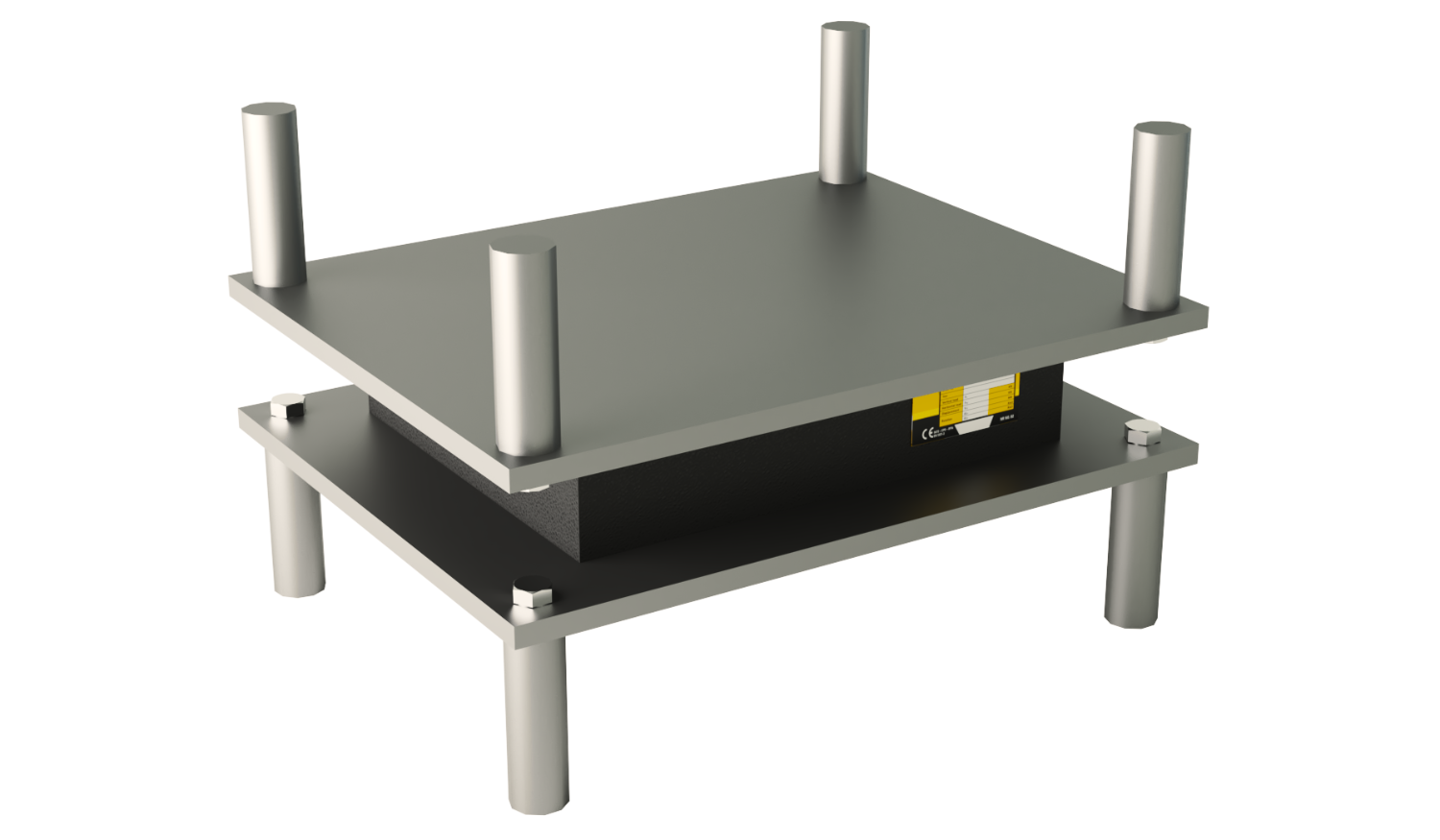

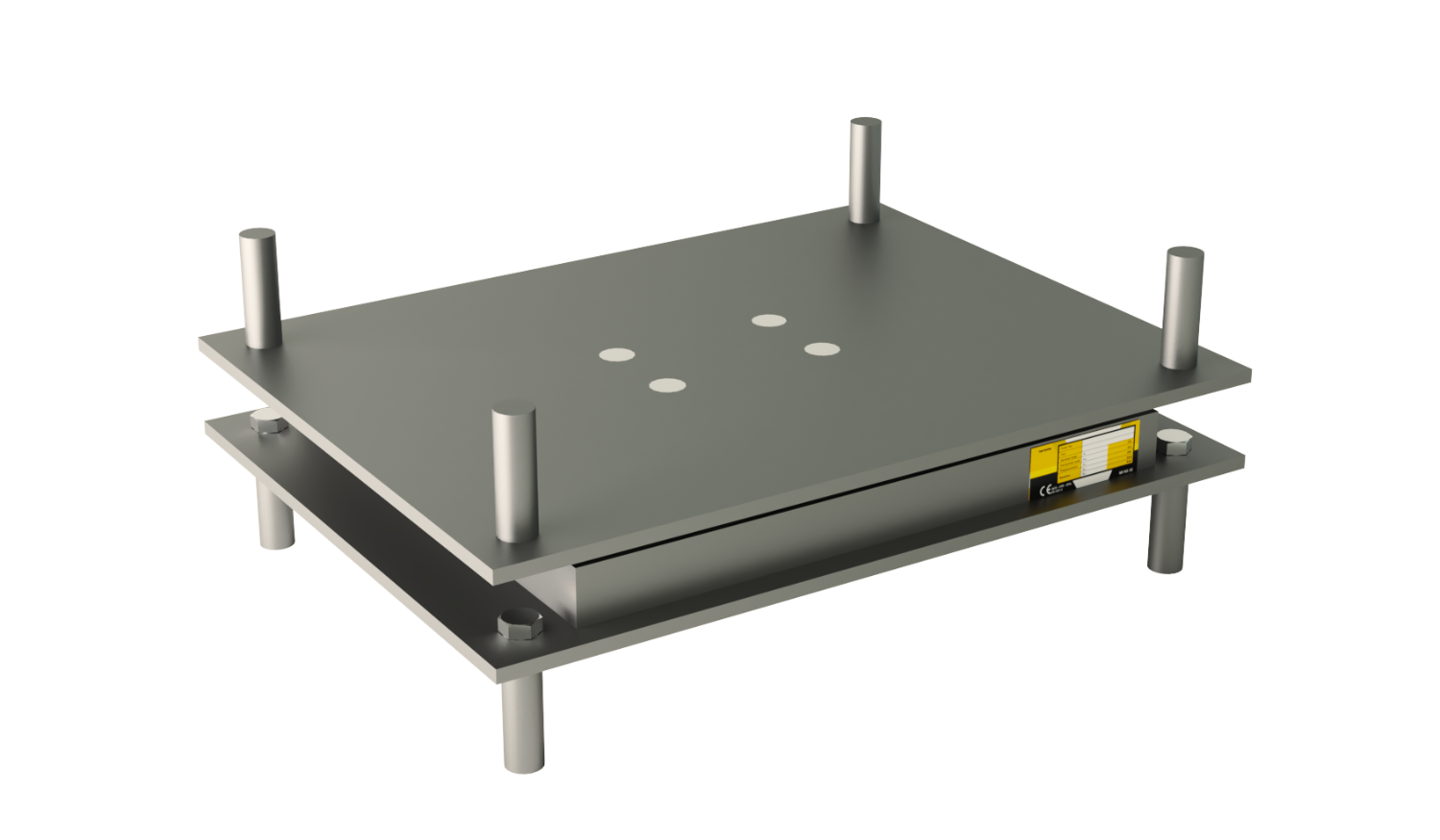

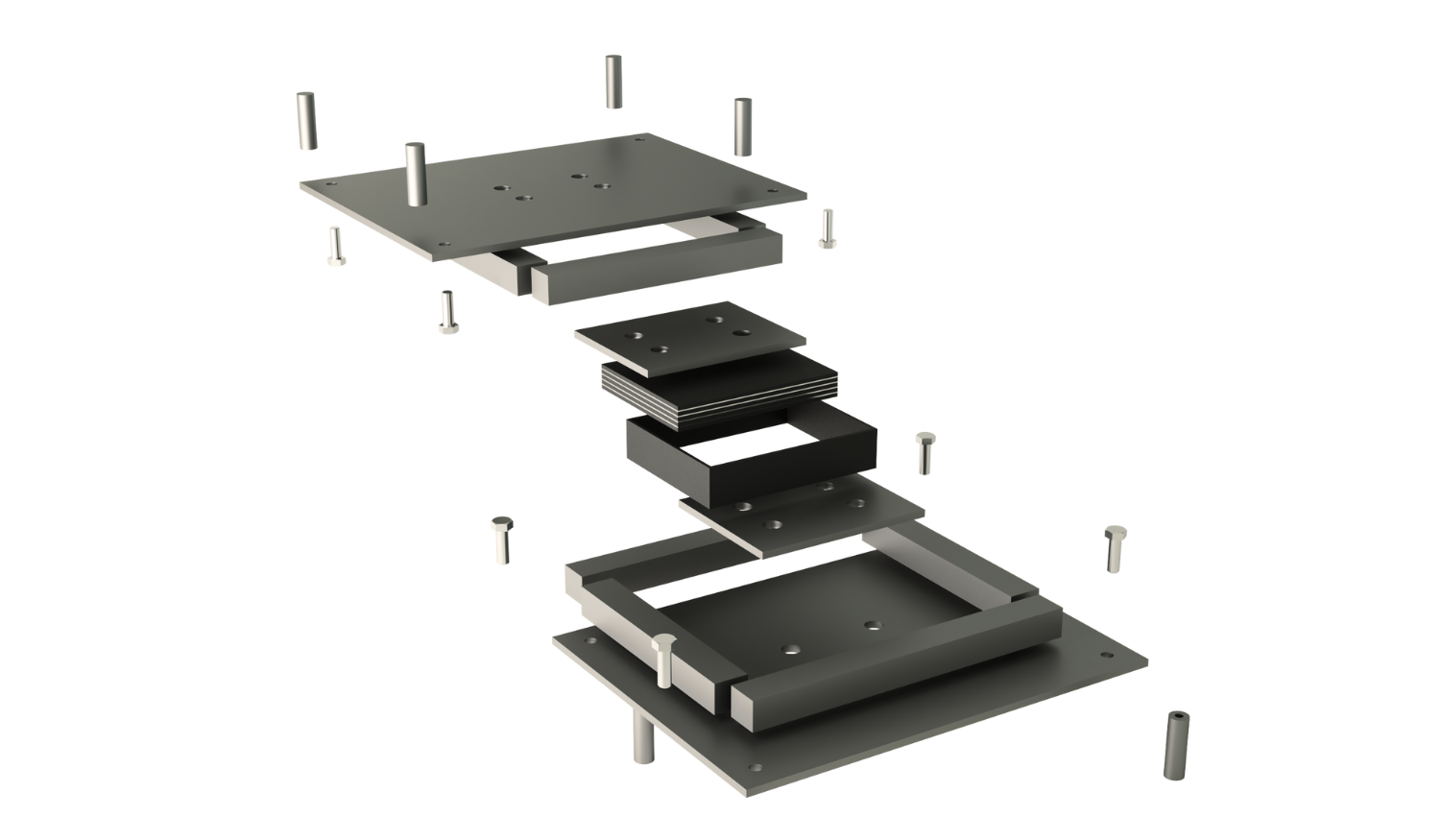

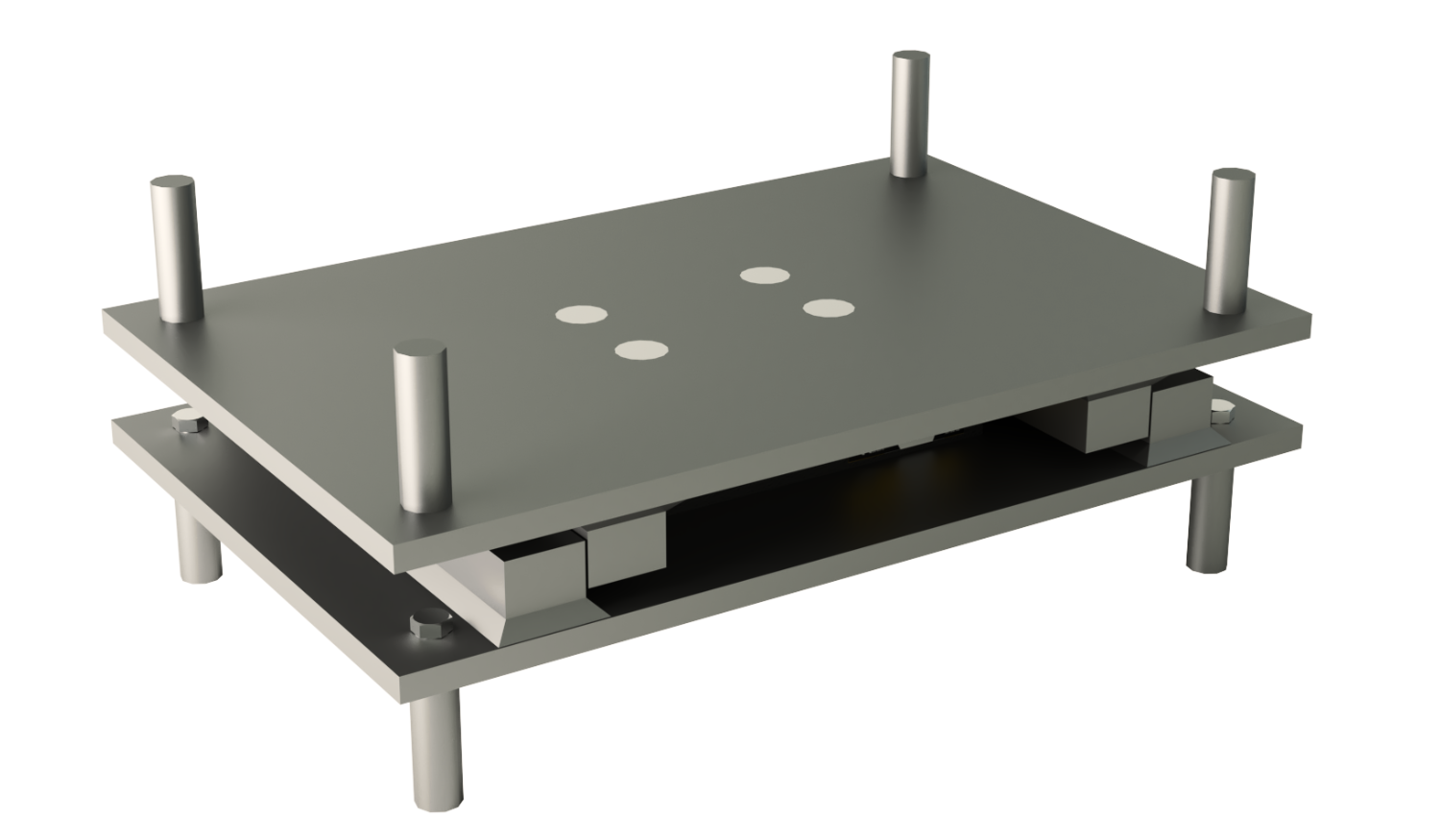

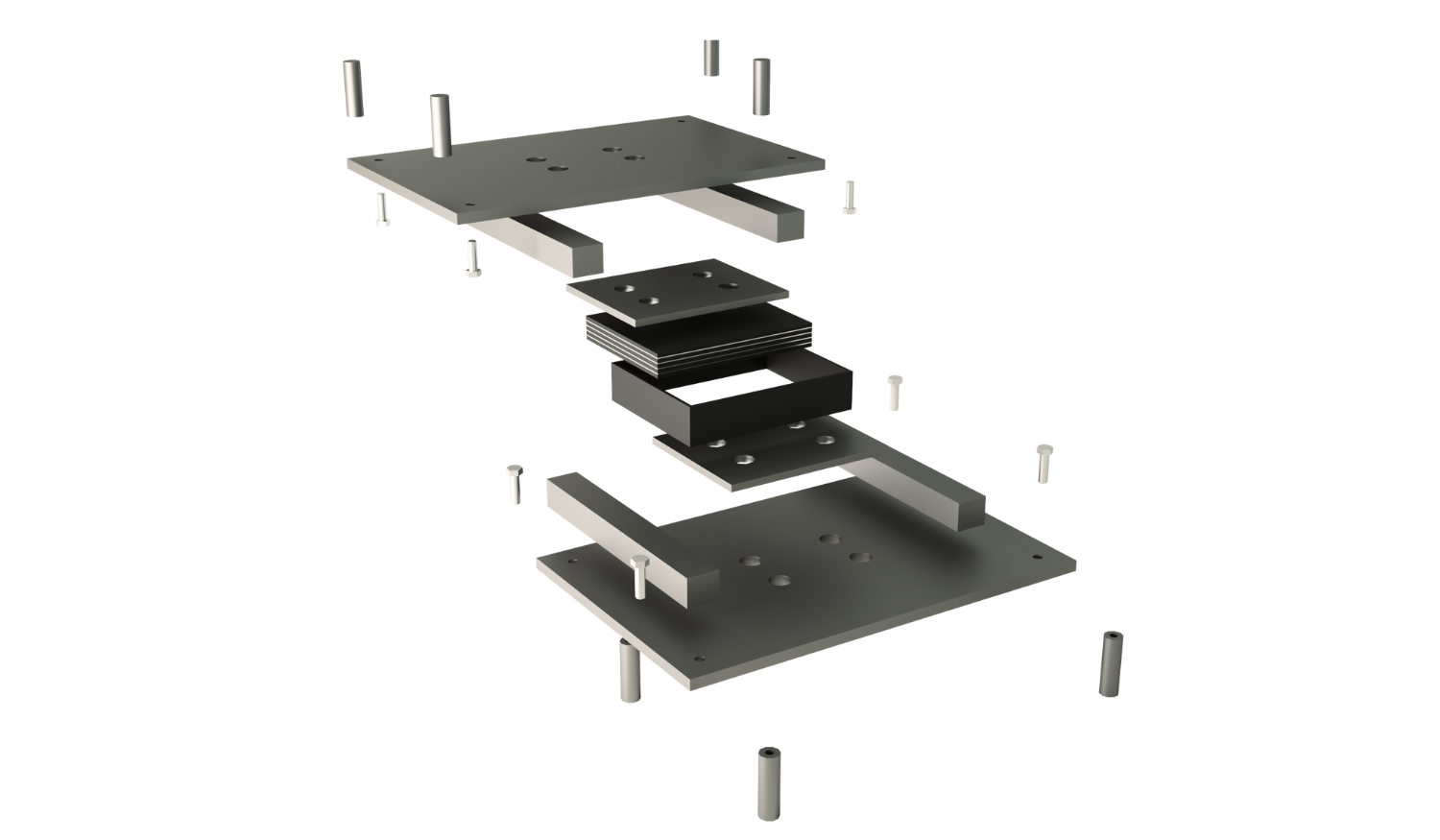

ELASTO FIXED BEARING

Same as type C between 2 steel

plates with welded restraints to transfer the horizontal loads in

every direction. They prevent horizontal displacements in any direction.

ELASTO GUIDED BEARING

Same as type C between 2 steel plates with welded restraints

to transfer the horizontal load in the transversal direction.

They allow horizontal displacements only along one direction.

The loading limits given in this table correspond to the loading of a bearing device to the ULS, in accordance with the verif cation requirments of standard EN 1337-3.

• The different values shown below in this table may be changed as a function of the actual load on the bearing given by consultant.

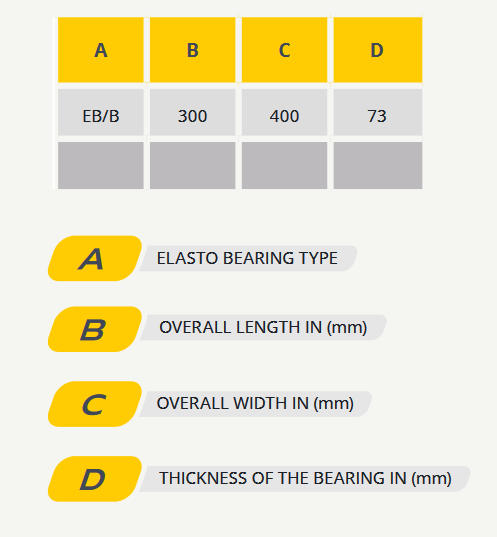

• Each rubber bearing is identif ed with the acronym EB (ELASTO BEARING).

• The numbers listed below represent plan dimensions and height of the Bearing.

TO CALCULATE THE TOTAL THICKNESS OF THE ELASTO

BEARING Type b

Tb= nr x ti+ ns x ts+ tc1+tc2

nr: Number of Rubber Layers = 4

ti : Elastomeric layer thickness = 12 mm

ns : Number of steel types = 4 + 1 = 5

ts : Steel Layer thickness = 4 mm

tc1,2: Top and bottom cover thickness = 2.5 mm

Tb= (4×12) + (Sx4) + (2.5+2.5 )=73mm