Spherical Bearings

INTRODUCTION

Spherical Bearings

ATAYA’s Spherical Bearings: Engineered for high

endurance and large movements Railway bridges

and long spans require high strength bearings that

accomodate large displacements, high vibrations and

can withstand very high compressive loads .

These versatile bearings come in various

configurations that comply with the EN 1337-7

standard. This ensures you get the perfect solution

for your bridge’s specific needs, whether it requires

handling horizontal translation, accommodating

rotation, or both.

By incorporating ATAYA’s Spherical -Bearings, you’re

investing in bearing that is durable for 100 years with

no requirement for replacement

Spherical Bearings Features & Performance

VERY LOW SLIDING CO-EFFICIENT OF FRICTION

NO MAINTENANCE

HIGH DURABILITY

UNLIMITED MOVEMENT CAPACITY

EASY INSPECTION

EASY INSTALLATION

HIGHEST ROTATION CAPACITY

SUITABLE FOR STEEL AND CONCRETE BRIDGES

LIFE TIME OF 100 YEARS WITH NO REPLACEMENT

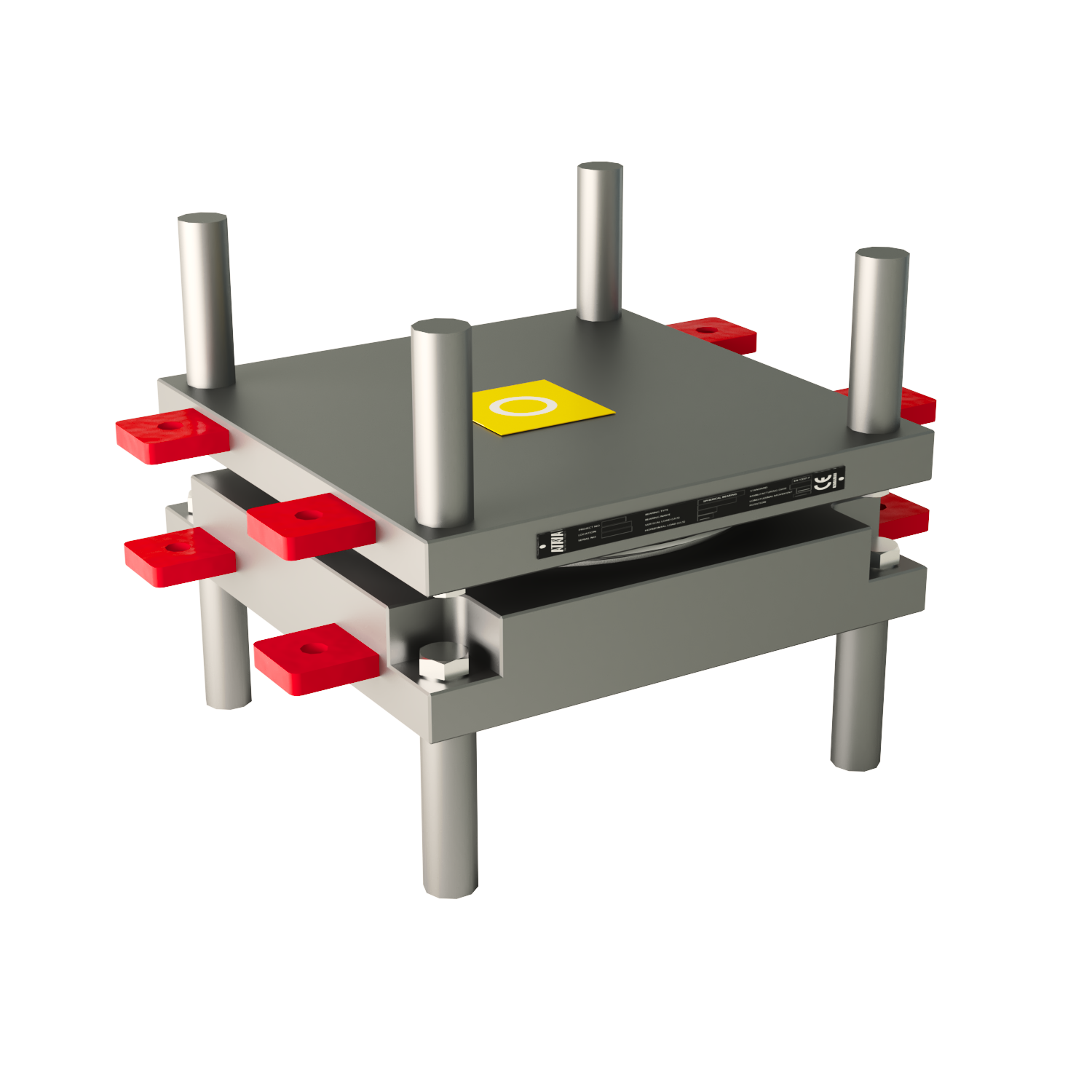

Type of Spherical Bearings

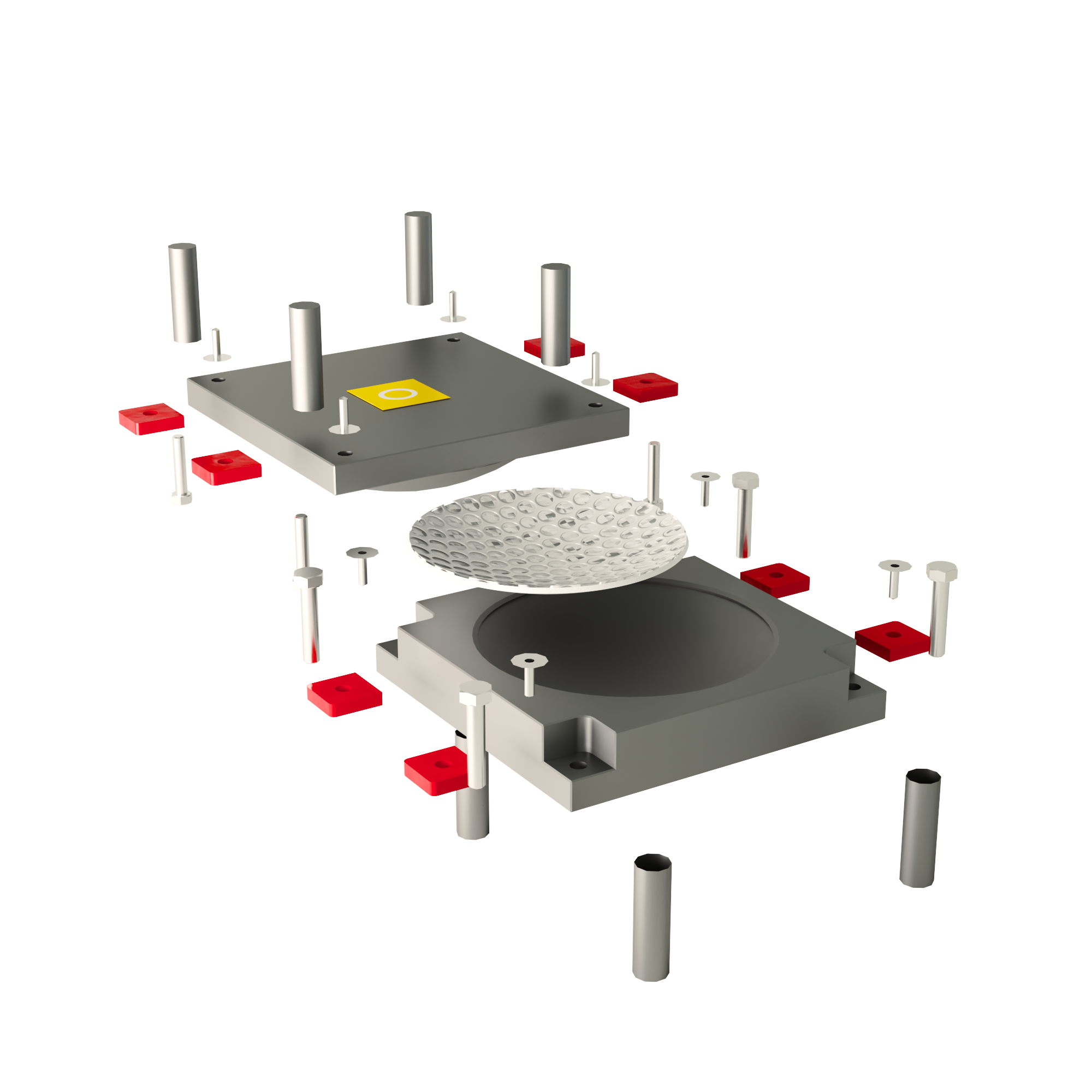

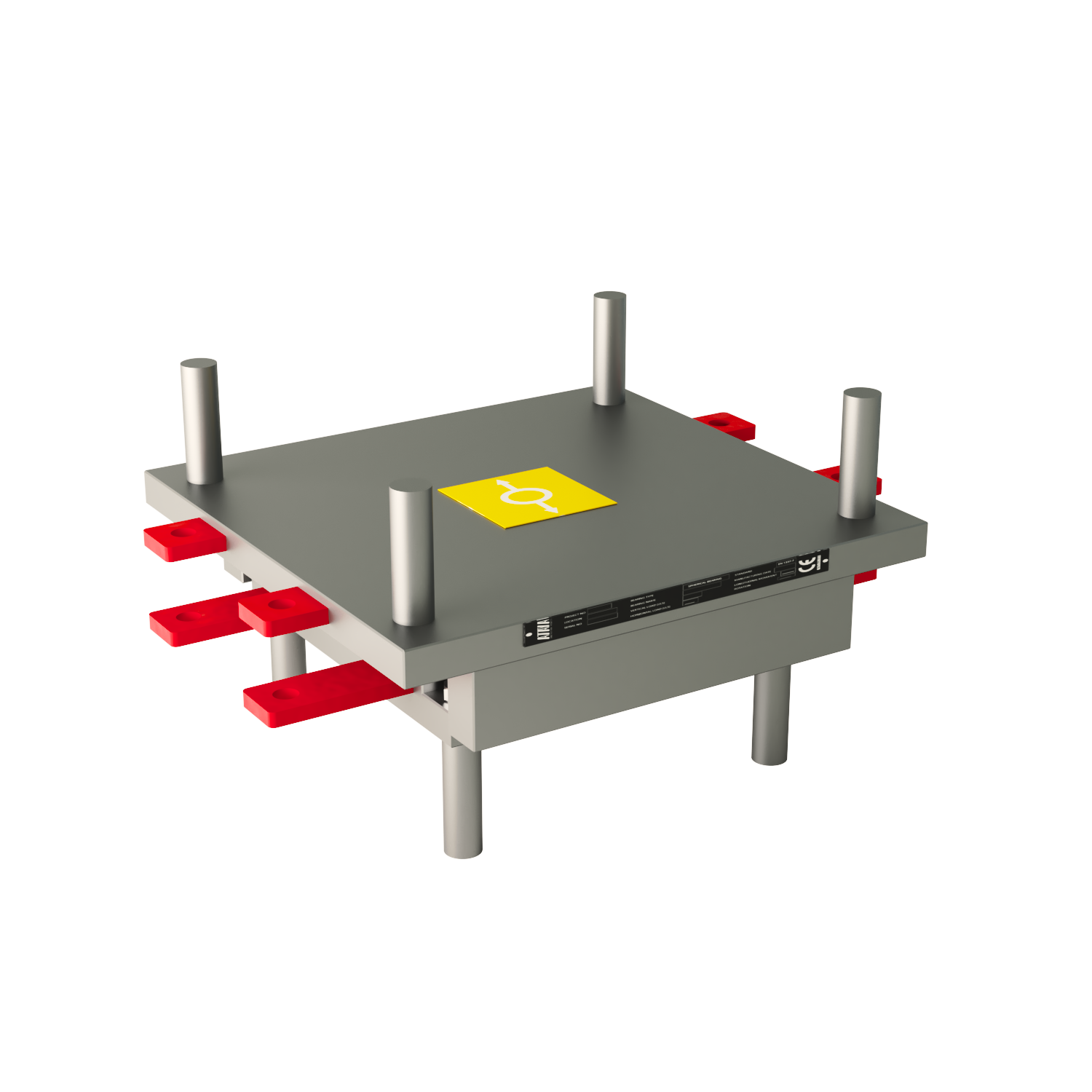

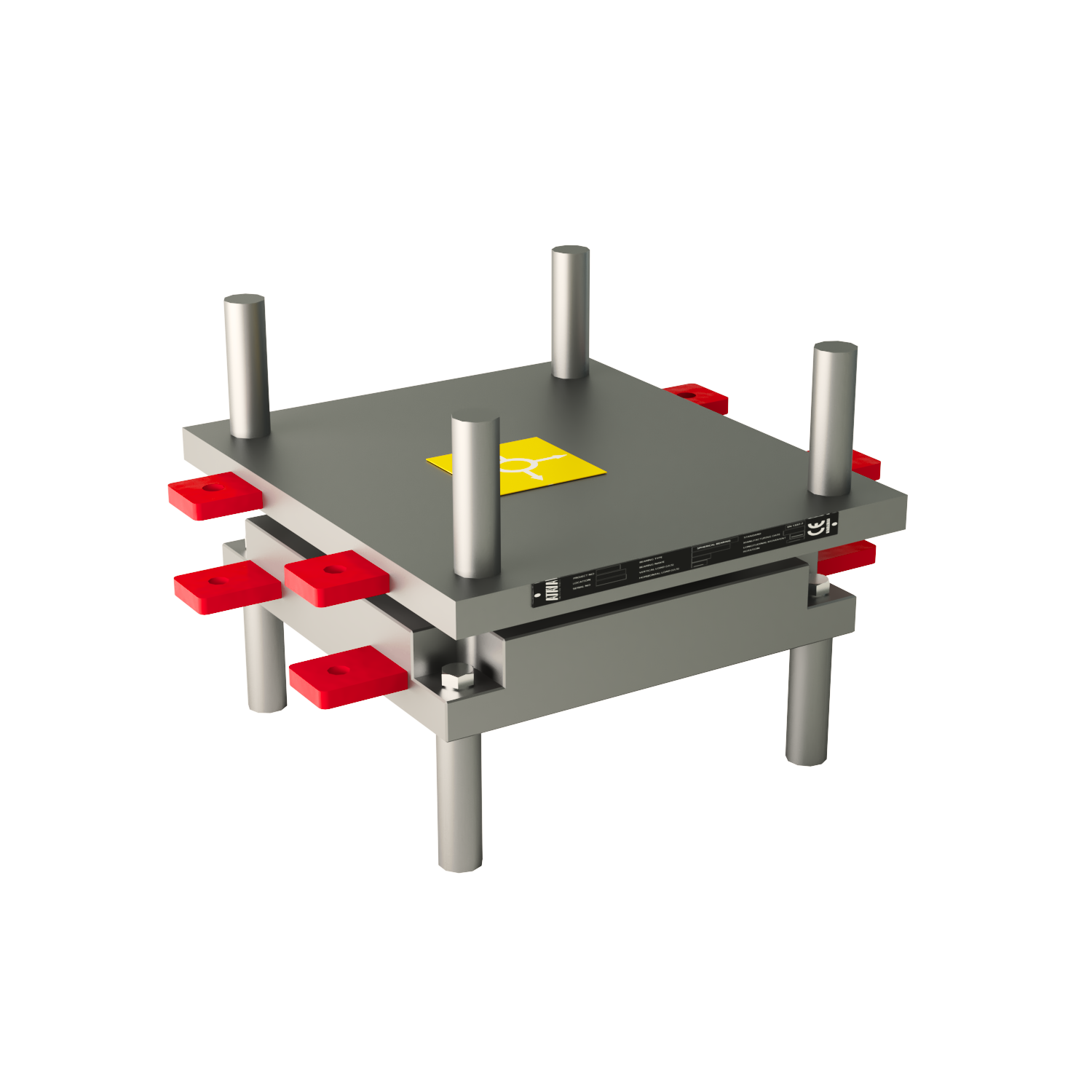

FIXED SPHERICAL BEARING

This type of bearings is restrained from horizontal movement in all directions while allowing rotation in all directions.

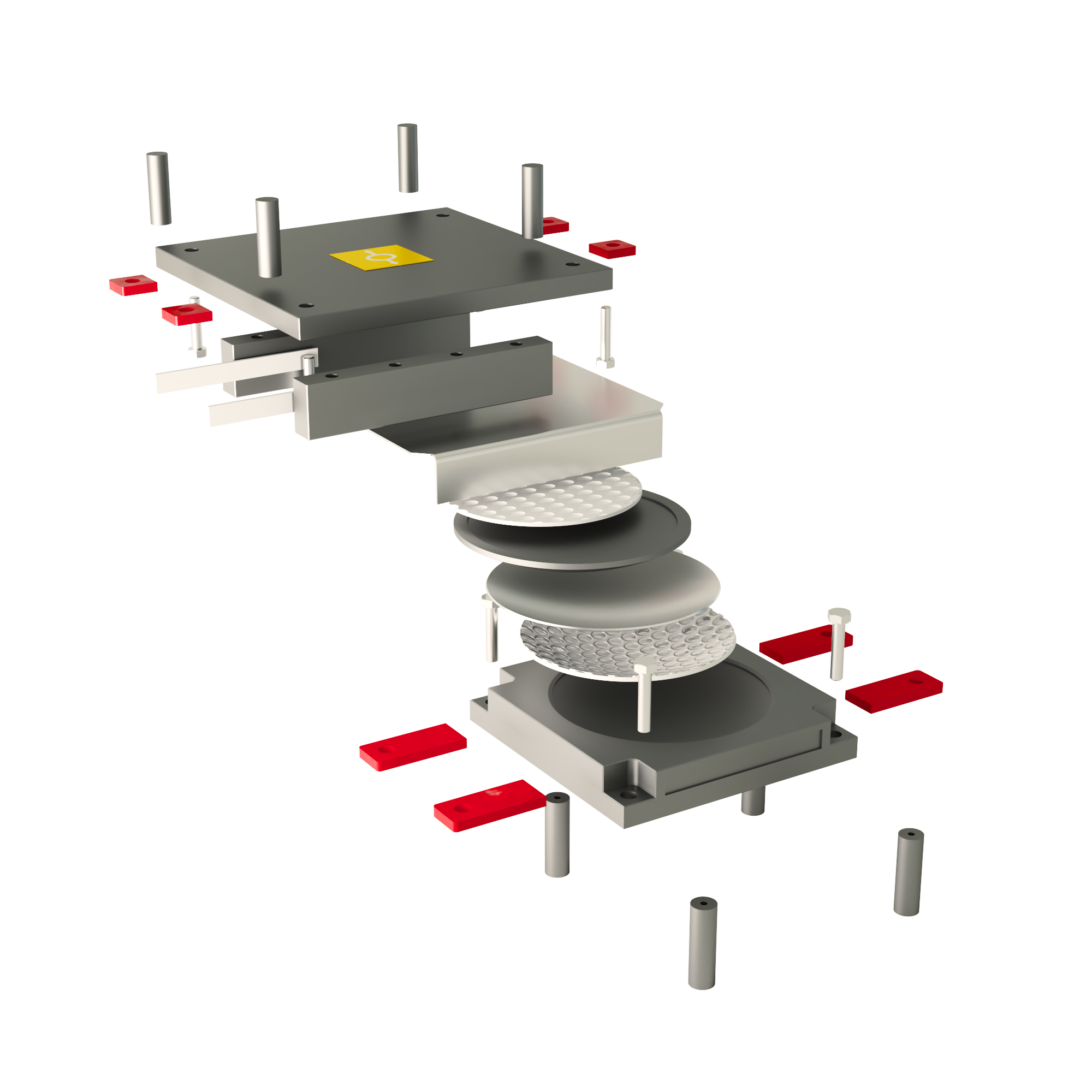

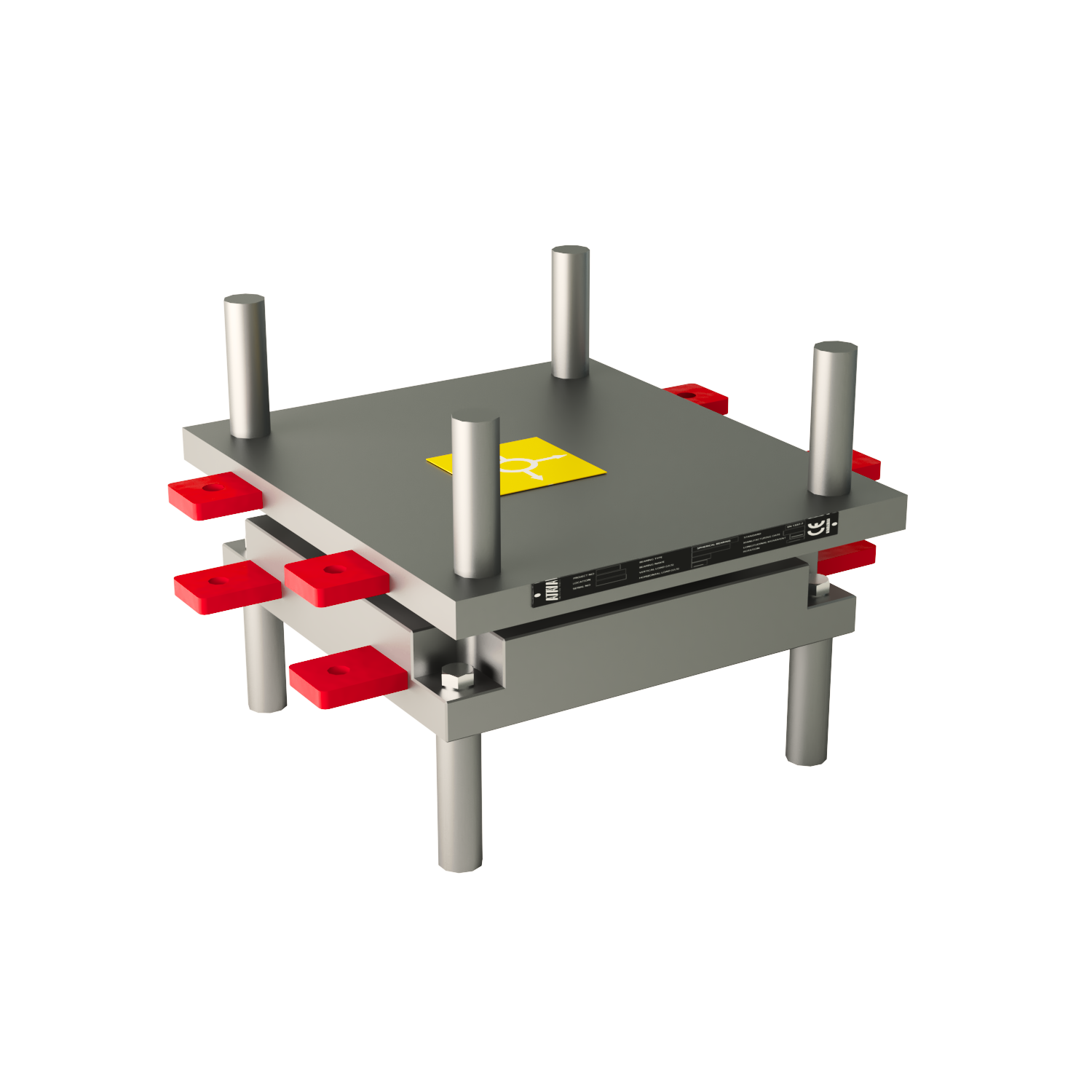

Guided Spherical Bearing

This type of bearings allows movement along only one axis

and rotation in all directions.

Free Sliding Spherical Bearing

This type of bearings allows movements and rotation in all directions.

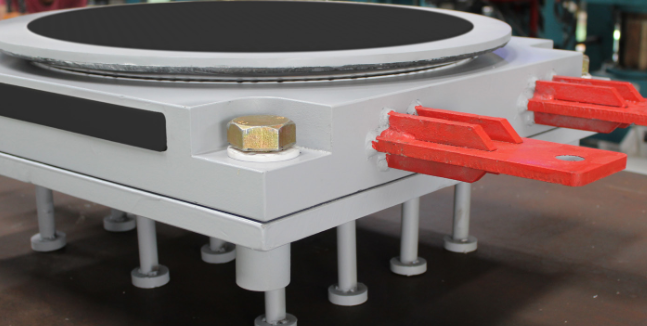

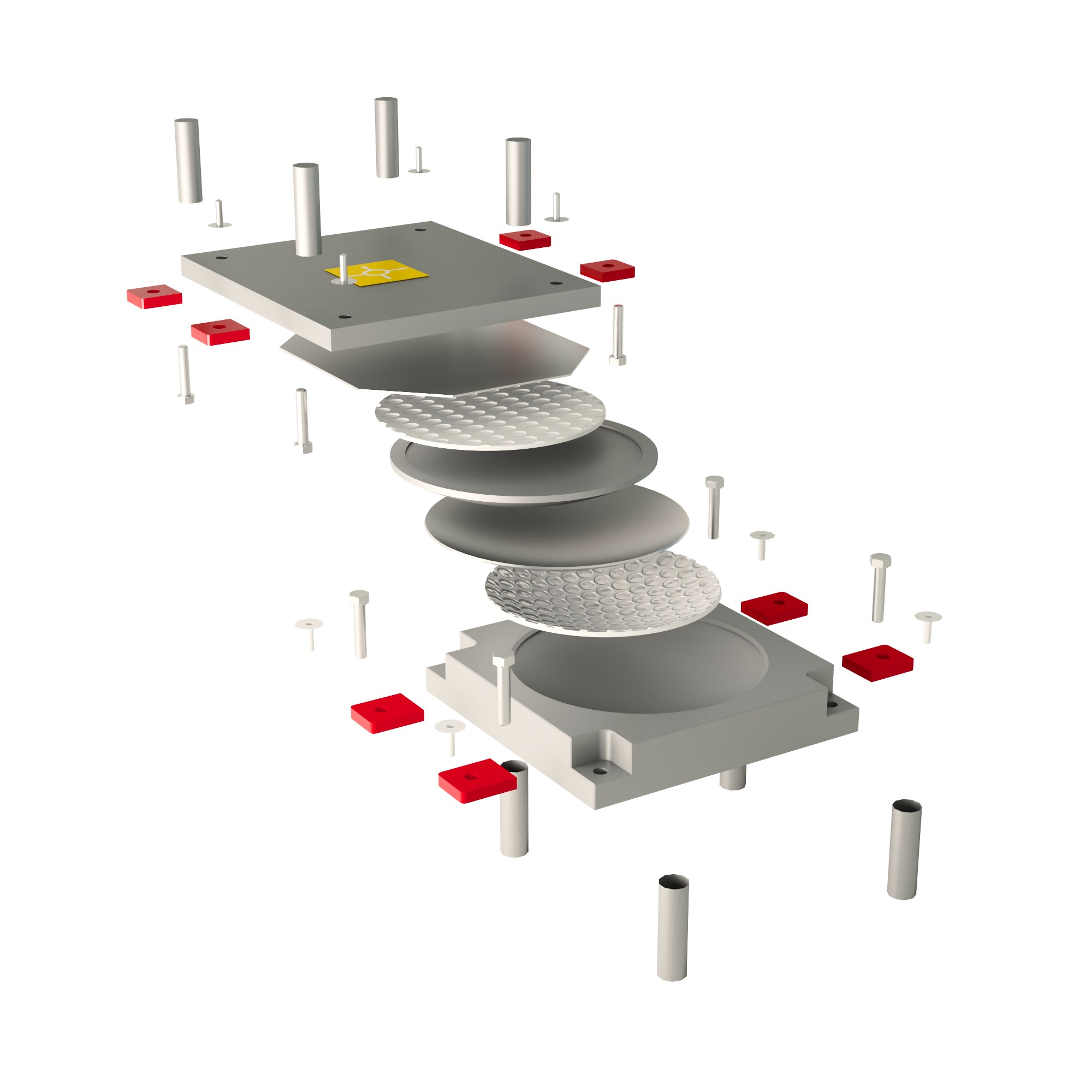

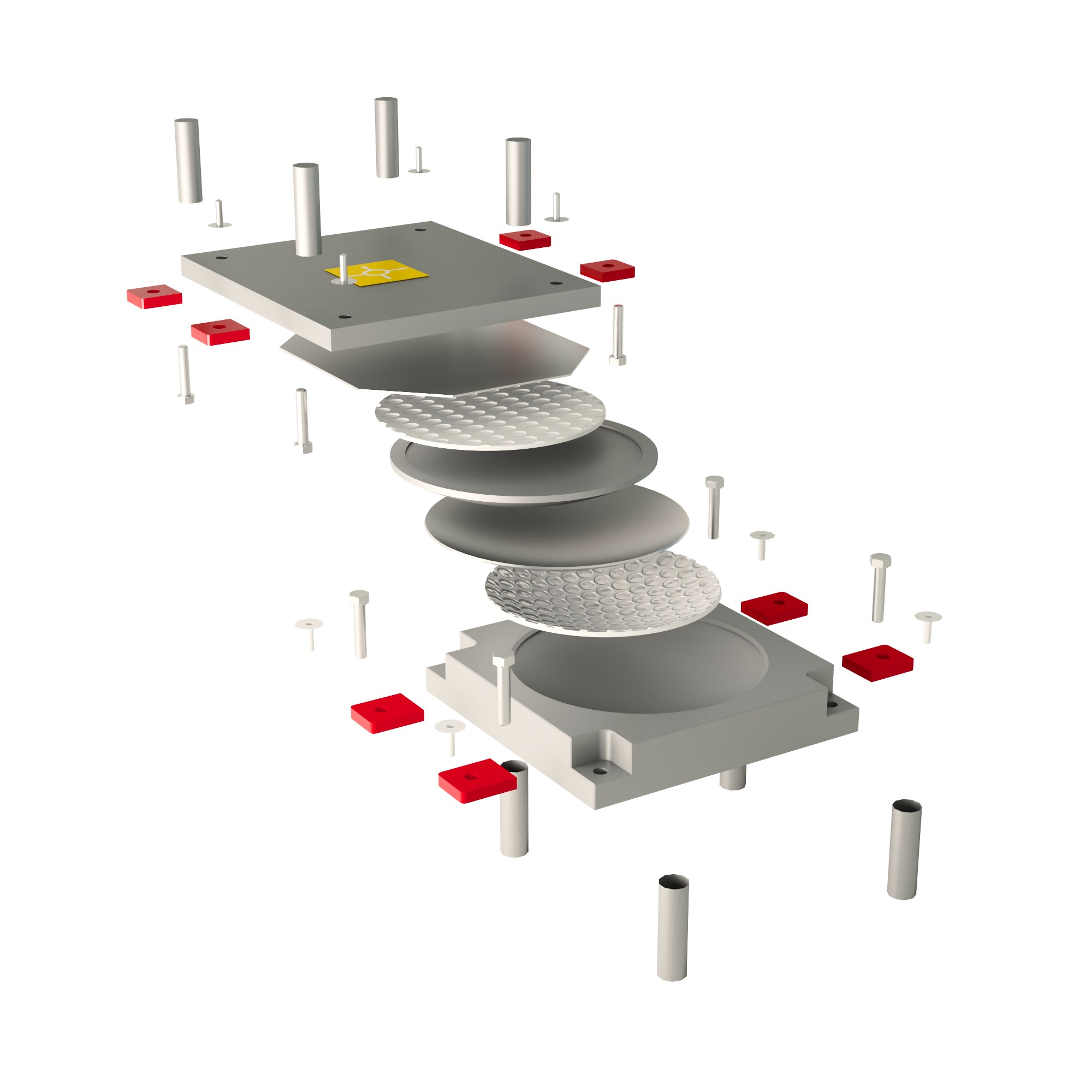

Beaings Components

UPPER BACKING PLATE (SOLE PLATE)

Transfers super structure loads to the bearing and provides a

stainless steel sliding surface for super structure transition.

CONVEX STEEL PLATE

Provides ASM® sliding surface for upper backing plate and

stainless steel mating surface for rotation on ASM® concave

surface

CONCAVE STEEL PLATE

Provides ASM® concave surface for rotation.

LOWER BACKING PLATE (MASONRY PLATE)

A steel lower part with a concave seat for the sliding material

and suitable connections to the substructure.

GUIDE BAR

Guide bar in guided bearings only (if required) to allow

movement in one direction.

RESTRAINING RING

It is used only in fixed bearings (if required) to restrain

the movements in all direction

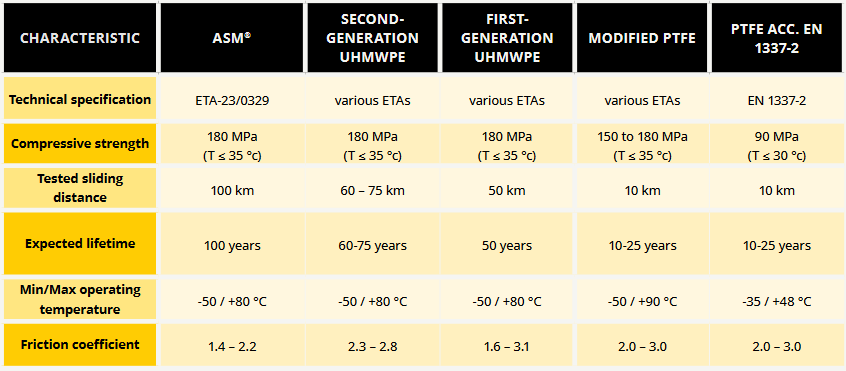

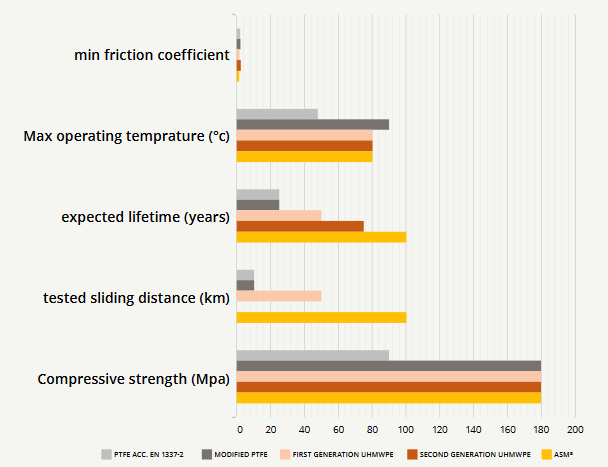

mATERIAL SPECIFICATIONS

Use of ASM® as sliding material in structural bearings is covered by the European Technical Assessment ETA-23/0329 based on the European Assessment Document EAD 050004-00-0301 issued by OIB (Austrian Building Institute).

Next table compares the performances of ASM® to those of conventional PTFE according to EN 1337-2 and first and second- generation UHMWPEs according to various ETAs.