Elastomeric Bearings: The Key to Smooth and Resilient Infrastructure

Introduction:

What are Elastomeric Bearings?

Elastomeric bearings are essential components used in construction and civil engineering to support structures while allowing for movement. Made primarily from rubber, these bearings absorb vibrations and accommodate shifts caused by thermal expansion, seismic activity, and traffic loads. They come in various shapes and sizes, tailored to specific applications while providing a flexible yet robust support system.

Significance of Elastomeric Bearing in Infrastructure

The role of elastomeric bearing extends beyond mere support; they contribute significantly to the longevity and safety of infrastructure. Here’s why they matter:

- Vibration Dampening: Reduces wear on structures.

- Cost-Effective: Lower maintenance costs due to their durability.

- Enhanced Performance: Improves resistance to environmental factors.

Examples from bridges and high-rise buildings showcase how elastomeric bearing enhance resilience and reliability in infrastructure projects, ensuring a safer future for urban environments.

Functionality and Benefits

Mechanism of Elastomeric Bearings

Elastomeric bearings operate through a clever combination of compressible rubber layers, which allow for controlled movement while bearing substantial loads. As structures experience shifts, these bearings deform, absorbing stress and providing stability.

- Flexibility: They can easily adapt to fluctuations without compromising structural integrity.

- Energy Absorption: Helps in mitigating the effects of seismic waves during an earthquake.

Advantages of Implementing Elastomeric Bearings

The benefits of elastomeric bearing extend far beyond their basic function:

- Cost Efficiency: They require minimal maintenance, translating into savings over time.

- Improved Lifespan: With superior durability, they extend the overall lifespan of infrastructure.

- Safety Enhancement: By providing stability, they protect against structural failures.

In practice, engineers have reported remarkable results, showcasing enhanced safety and performance across various projects, such as the iconic Golden Gate Bridge retrofit.

Applications in Infrastructure

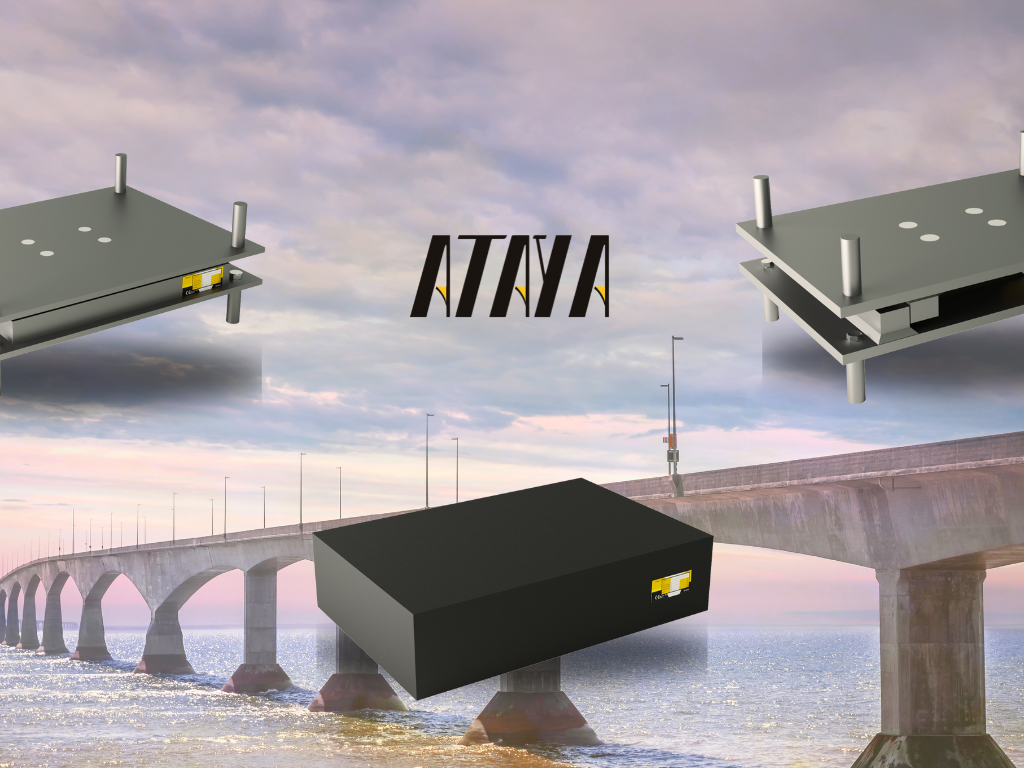

Elastomeric Bearings in Bridges

Elastomeric bearing are pivotal in bridge construction and maintenance. They absorb the stresses from vehicular loads and environmental factors, ensuring the bridge remains stable and operational. Many iconic bridges utilize these bearings, providing a safe passage for millions.

- Load Distribution: They evenly spread forces along the bridge structure.

- Seismic Resilience: Help minimize damage during earthquakes by allowing for movement.

Elastomeric Bearings in Buildings

In high-rise buildings, elastomeric bearings are crucial for managing sway and dynamic loads from wind. They provide much-needed flexibility without sacrificing strength.

- Foundation Support: They enhance foundation stability by accommodating shifts.

- Comfort Enhancement: Help minimize vibrations felt by occupants during events like earthquakes or heavy winds.

Real-world experiences in skyscrapers such as the Burj Khalifa highlight how elastomeric bearings improve structural integrity and occupant safety.

Design and Installation Guidelines

Factors to Consider in Bearing Design

When designing elastomeric bearings, several key factors come into play to ensure optimal performance:

- Load Capacity: The bearings must be designed to handle anticipated loads without failure.

- Environmental Conditions: Considerations such as temperature extremes and exposure to chemicals are crucial.

- Movement Requirements: Assess the expected vertical and horizontal movements to determine bearing thickness and shape.

Each project merits careful evaluation to tailor the design effectively.

Procedures for Installing Elastomeric Bearings

Proper installation of elastomeric bearing is essential for performance. Here’s a general procedure:

- Site Preparation: Ensure a clean, level surface for placement.

- Alignment: Position bearings accurately to align with structural components.

- Secure Fastening: Use appropriate anchoring techniques to ensure stability.

Following these guided steps can prevent common installation pitfalls, as shared by seasoned engineers who have learned from firsthand experiences.

Maintenance and Inspection

Importance of Regular Maintenance

Regular maintenance of elastomeric bearing is crucial to ensure their longevity and effectiveness. Neglecting this aspect can lead to structural issues that compromise safety and performance.

- Preventative Care: Routine inspections can identify wear and tear before it escalates.

- Cost Efficiency: Early detection of problems can save substantial repair costs in the long run.

Construction professionals often share that a proactive maintenance approach can extend the lifecycle of bearings significantly, offering peace of mind.

Techniques for Inspecting Elastomeric Bearings

Inspection techniques for elastomeric bearings include:

- Visual Inspections: Checking for surface cracks or deformations.

- Load Testing: Assessing the bearing’s response under different loads.

- Thermal Imaging: Identifying heat variations that may indicate structural issues.

Implementing these methods ensures that bearings remain in optimal condition, fostering safety and reliability for infrastructure that countless people depend on daily.

Performance and Longevity

Durability of Elastomeric Bearings

One of the standout characteristics of elastomeric bearings is their remarkable durability. Made from high-performance rubber compounds, they are engineered to withstand extreme conditions.

- Weather Resistance: They can endure varying temperatures and weather patterns.

- Fatigue Resistance: Designed to absorb repeated stress without degrading.

For example, many bridges have seen elastomeric bearings maintain their strength for decades, showcasing their long-lasting reliability.

Factors Affecting Performance Over Time

Despite their durability, certain factors can influence the performance of elastomeric bearing:

- Environmental Exposure: UV radiation and chemical exposure can cause deterioration.

- Load Cycles: Frequent heavy loads may lead to fatigue over time.

- Temperature Fluctuations: Extreme heat or cold can affect material properties.

By proactively assessing these factors, engineers can better maintain the effectiveness of elastomeric bearing, ensuring they meet their intended lifespan and functionality.

Case Studies and Success Stories

Real-world Examples of Elastomeric Bearings in Action

Elastomeric bearing have proven their worth in numerous projects worldwide. For example, the Melbourne Star Observation Wheel successfully employs these bearings to provide stability and dampen vibrations, ensuring a smooth experience for riders.

- Golden Gate Bridge Retrofit: Updates included elastomeric bearing that improved earthquake resilience.

- London’s Thames Barrier: These bearings contribute to the system’s ability to withstand dynamic forces.

Impact on Infrastructure Resilience

The implementation of elastomeric bearing directly impacts the resilience of infrastructure. Their ability to absorb shocks and accommodate movement allows structures to withstand dynamic forces such as earthquakes and heavy traffic.

- Safety Enhancements: They significantly reduce the risk of structural failures.

- Longevity: Projects utilizing elastomeric bearing often see extended lifespans, highlighting their value in sustainable construction practices.

These success stories not only showcase the effectiveness of elastomeric bearing but also reinforce their role in creating safer, more resilient infrastructures for future generations.

Future Trends and Innovations

Ongoing Research and Development

The field of elastomeric bearing is continuously evolving, powered by ongoing research and development efforts. Engineers and material scientists are focusing on enhancing the material properties to improve performance under extreme conditions.

- Smart Materials: Research is exploring the use of smart materials that can adapt to changing environmental conditions.

- Sustainability: New eco-friendly materials are being developed to reduce the carbon footprint of production.

These advancements aim to make elastomeric bearing more efficient and environmentally friendly.

Emerging Technologies in Elastomeric Bearings

Innovative technologies are also making their way into elastomeric bearing applications. For instance:

- 3D Printing: Allows for tailored designs that meet specific project needs.

- Sensor Integration: Equipped with sensors, bearings can now provide real-time data on stress and load conditions.

These trends signal an exciting future where elastomeric bearings become even more integral to resilient infrastructure. As projects adopt these innovations, they will enhance safety, efficiency, and sustainability in construction practices.

Conclusion

Recap of Elastomeric Bearings' Role in Infrastructure

Throughout this exploration of elastomeric bearings, their vital contribution to infrastructure safety and durability has been clear. These reliable components not only enhance the performance of bridges and buildings but also significantly extend their lifespan through effective stress and vibration management.

- Safety Enhancements: By absorbing shocks, they protect structures from environmental stresses.

- Cost-Effectiveness: Their durability leads to lower maintenance costs over time.

The Future Outlook for Elastomeric Bearings

Looking ahead, the future of elastomeric bearing appears bright. With continuous advancements in research and technology:

- Innovation: Expect smarter, more adaptive bearings equipped with real-time sensors.

- Sustainability: Eco-friendly materials will likely become the norm in production.

As these innovations unfold, elastomeric bearing will play an even more crucial role in building resilient infrastructure for future generations, ensuring safety and sustainability for communities worldwide.