Expansion Joints Bridge in Construction: Ensuring Durability and Safety

Introduction:

Expansion joint bridge construction is crucial for ensuring durability, safety, and longevity. Expansion joints play a vital role in achieving these objectives. This article explores the importance of expansion joints in bridge construction, covering their types, design considerations, and maintenance strategies, offering a comprehensive guide for engineers, architects, and construction professionals.

What Are Expansion Joints?

Joints are essential components in bridge construction that allow for movement and flexibility. They accommodate the expansion and contraction of bridge materials caused by temperature fluctuations, traffic loads, and other environmental factors. Without these joints, bridges would be susceptible to damage, leading to costly repairs and potential safety hazards.

Ensuring Structural Integrity

Expansion joints prevent structural damage by absorbing the stresses and strains that occur due to thermal expansion, contraction, and other dynamic forces. By allowing controlled movement, they help maintain the structural integrity of the bridge, preventing cracks, fractures, and other forms of deterioration.

Enhancing Safety

Safety is a top priority in bridge construction. Expansion joints contribute to safe travel by providing a smooth transition between bridge sections. They minimize the impact of dynamic forces on the structure, reducing the risk of accidents and ensuring a comfortable ride for vehicles.

Types of Expansion Joints in Bridge Construction

1. Modular Expansion Joints

Modular joints play a crucial role in the safety and longevity of modern bridges. As adaptable components, they are designed to accommodate significant movements and dynamic forces, making them essential for bridges subject to varying environmental conditions and heavy traffic loads.

What Are Modular Expansion Joints?

Modular joints are composed of multiple interlocking units, allowing for extensive thermal expansion and contraction. These joints are particularly favored for long-span bridges or those in areas with extreme temperature fluctuations.

Key Benefits

- Durability: Modular joints offer exceptional durability and resilience against wear and tear, ensuring long-term performance.

- Load-Bearing Capacity: Designed to handle heavy traffic loads, they provide reliable support for high-volume vehicular movement.

- Multi-Directional Flexibility: These joints can accommodate movements in multiple directions, making them suitable for complex bridge designs and seismic-prone areas.

Design and Installation Considerations

When implementing modular expansion joints, engineers must consider factors such as the expected traffic load, environmental conditions, and joint alignment. Proper installation and alignment are critical to prevent undue stress on the joint components.

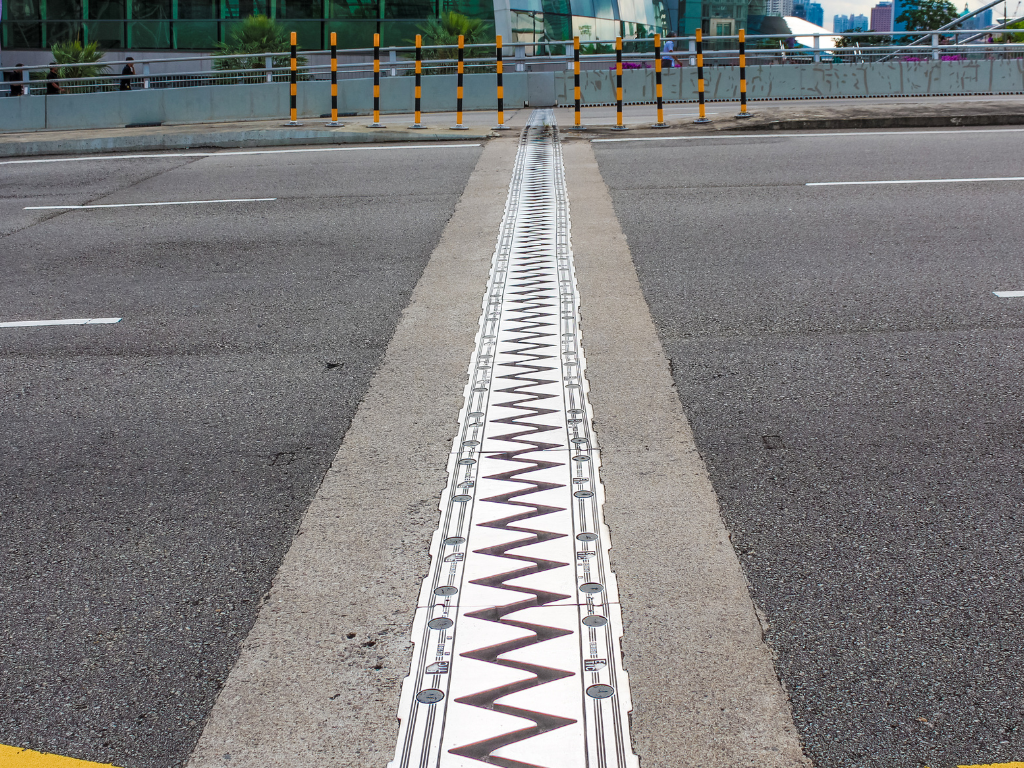

2. Finger Expansion Joints

Finger expansion joints are critical components in bridge construction, designed to facilitate controlled movement while ensuring structural integrity. Their unique interlocking design allows for moderate movement accommodation, making them an essential choice for many short to medium-span bridge projects.

What Are Finger Expansion Joints?

Finger expansion joints consist of interlocking steel plates that resemble fingers, allowing bridges to expand and contract with temperature changes and dynamic forces. These joints are favored for their simplicity and effectiveness in managing structural movement.

Key Benefits

- Cost-Effectiveness: Finger joints provide a budget-friendly solution for expansion needs, with a straightforward design that simplifies installation and maintenance.

- Durability: Engineered to withstand moderate traffic loads, they offer reliable performance over time, resisting wear and tear.

- Easy Maintenance: Their simple structure allows for easier inspection and maintenance, reducing downtime and extending the bridge’s service life.

Design and Installation Considerations

When selecting finger joints, engineers must assess factors such as anticipated movement range, traffic load, and environmental exposure. Proper alignment and installation are crucial to avoid stress concentrations and ensure optimal performance.

3. Elastomeric Expansion Joints

Elastomeric expansion joints are crucial components in bridge construction, designed to absorb movements and vibrations while maintaining structural integrity. These flexible joints are particularly valuable in accommodating a variety of bridge movements, including thermal expansion, contraction, and seismic activity, making them indispensable for projects in dynamic environments.

What Are Elastomeric Expansion Joints?

Elastomeric joints consist of flexible rubber materials that allow bridges to expand and contract while absorbing vibrations. Their adaptability makes them a preferred choice for bridges in earthquake-prone regions and those subject to significant temperature fluctuations.

Key Benefits

- Flexibility: Elastomeric joints offer superior flexibility, enabling them to accommodate multi-directional movements and adapt to various environmental conditions.

- Vibration Absorption: These joints effectively dampen vibrations, enhancing ride comfort and reducing stress on structural elements.

- Durability: Made from resilient materials, elastomeric joints are resistant to wear and tear, ensuring long-lasting performance even under challenging conditions.

Design and Installation Considerations

When implementing elastomeric expansion joints, engineers must consider factors such as expected movement range, environmental exposure, and traffic load. Proper material selection and installation are critical to achieving optimal performance and longevity.

4. Asphaltic Plug Joint

An asphaltic plug joint (APJ) is a type of expansion joint commonly used in bridge construction and rehabilitation. Here are the key features and functions of asphaltic plug joints:

What Are Elastomeric Expansion Joints?

Asphaltic plug joints are particularly suited for new and rehabilitated bridges, providing a smooth transition between the bridge deck and abutments while allowing for necessary movement without compromising structural integrity.

Key Benefits

- Waterproofing:

- One of the primary benefits of an asphaltic plug joint is its ability to provide a waterproof seal, preventing water and debris from infiltrating the joint area, which can lead to deterioration.

- Durability:

- While APJs are generally durable, their performance can be affected by temperature variations. High temperatures may lead to issues like rutting or delamination, while low temperatures can cause cracking.

- Ease of Installation:

- Asphaltic plug joints are relatively easy to install compared to other types of joints. They can also be repaired segmentally, which minimizes disruption during maintenance.

- Cost-Effectiveness:

- Generally, APJs are less expensive than many other expansion joint types, making them an attractive option for bridge projects.

- Maintenance Requirements:

- Regular maintenance is necessary to ensure longevity. This includes retightening bolts after installation and conducting annual inspections to check for wear or damage.

- Waterproofing:

Design and Installation Considerations

When implementing elastomeric expansion joints, engineers must consider factors such as expected movement range, environmental exposure, and traffic load. Proper material selection and installation are critical to achieving optimal performance and longevity.

Design Considerations for Expansion Joints

Environmental Factors

When designing expansion joints, engineers must consider the environmental conditions the bridge will face. Temperature variations, humidity, and exposure to harsh weather conditions can impact the performance of joints. Proper material selection and design specifications are crucial to ensure longevity and reliability.

Load-Bearing Capacity

The load-bearing capacity of joints is a critical consideration. Joints must be able to withstand the weight and dynamic forces of vehicles passing over the bridge. Engineers must calculate the expected load and select joints that can handle these demands without compromising safety.

Maintenance and Inspection of Expansion Joints

Routine Inspections

Regular inspections are essential to identify signs of wear and tear in joints. Engineers and maintenance teams should check for cracks, corrosion, and other forms of damage. Timely identification and repair of issues can prevent further deterioration and extend the lifespan of the bridge.

Maintenance Strategies

Proper maintenance strategies, including cleaning, lubrication, and sealing, can enhance the performance of joints. Routine maintenance not only ensures safety but also reduces the need for costly repairs and replacements.

Conclusion:

Joints are vital components in bridge construction, providing the flexibility and durability needed to withstand dynamic forces and environmental challenges. By understanding their importance, types, design considerations, and maintenance strategies, construction professionals can ensure the longevity and safety of bridges. Whether dealing with modular, finger, or elastomeric joints, a well-informed approach will lead to successful and resilient bridge projects.