Joints

Let's Choose

Choose Your Preferred Product

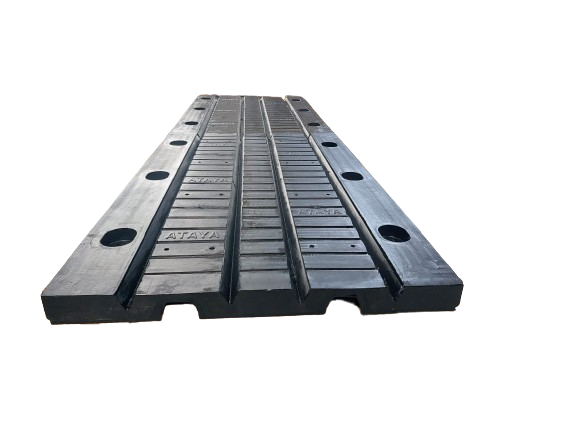

Elastomeric Expansion Joint

Rubber Expansion Joints designed to accommodate structure movement from ±50mm to ±100mm.The Expansion Joints system consists of molded rubber which is steel reinforced.

Asphaltic plug joints for bridge

ATAYA is an ENNIS FLINT approved applicator for the delivery and installation of the Thormajoint bridge joint range according to the specification of Asphaltic Plug Joint.

Expansion Bridge Joints: A Critical Component of Bridge Infrastructure

Bridges, as magnificent feats of engineering, are subjected to various stresses, including thermal expansion and contraction. To accommodate these movements and prevent structural damage, expansion joints are incorporated into their design. These ingenious devices allow for controlled movement between different sections of a bridge, ensuring its longevity and safety.

The Need for Expansion Joints

As temperatures fluctuate, materials expand and contract. For bridges, this can lead to significant dimensional changes, especially in long spans. Without expansion joints, these stresses could cause cracking, buckling, or even collapse. Expansion joints act as a buffer, absorbing the movement and preventing it from damaging the bridge structure.

Types of Expansion Joints

Various types of expansion joints are employed in bridge construction, each tailored to specific requirements:

Finger Joints:

- Composed of interlocking metal fingers that slide over each other.

- Suitable for moderate movement.

- Often used in older bridges.

Rubber Bearing Joints:

- Utilize rubber bearings to accommodate vertical and horizontal movement.

- Provide excellent sealing against water and debris.

- Commonly used in modern bridge designs.

Steel Plate Joints:

- Consist of steel plates that slide over each other, often with a watertight seal.

- Durable and reliable, but require careful maintenance to prevent corrosion.

- Consist of steel plates that slide over each other, often with a watertight seal.

Modular Expansion Joints:

- Pre-fabricated units that can be easily installed and replaced.

- Offer flexibility in design and accommodate various movement requirements.

- Pre-fabricated units that can be easily installed and replaced.

Key Considerations in Expansion Joint Design

Several factors influence the selection and design of expansion joints:

- Expected Movement: The amount of movement a bridge will experience due to temperature changes, traffic loads, and other factors.

- Environmental Conditions: Exposure to harsh weather, such as extreme temperatures, humidity, and corrosive substances, can impact the joint’s performance.

- Traffic Loads: The weight and frequency of vehicles crossing the bridge will affect the joint’s design and maintenance requirements.

- Aesthetics: The appearance of the joint should complement the overall design of the bridge.

Maintenance and Inspection

Proper maintenance of expansion joints is crucial to ensure their continued effectiveness. Regular inspections should be conducted to identify any signs of wear, damage, or deterioration. Common maintenance tasks include:

- Cleaning: Removing debris and contaminants that can hinder movement or accelerate corrosion.

- Lubrication: Applying appropriate lubricants to reduce friction and ensure smooth operation.

- Sealant Replacement: Replacing worn or damaged seals to prevent water infiltration.

- Structural Inspection: Checking for cracks, corrosion, or other structural defects.

By understanding the principles of expansion joints and their critical role in bridge engineering, we can appreciate the intricate details that go into designing and maintaining these vital structures.