Pot Bearings

INTRODUCTION

pOT Bearings

ATAYA’s Pot Bearings: Engineered for high endurance and large movements

Long spans require high strength bearings that accomodate large displacements and can withstand very high compressive loads .

These versatile bearings come in various configurations that comply with the EN 1337-5 standard. This ensures you get the perfect solution for your bridge’s specific needs, whether it requires handling horizontal translation, accommodating rotation, or both.

Type of POT BEARINGS

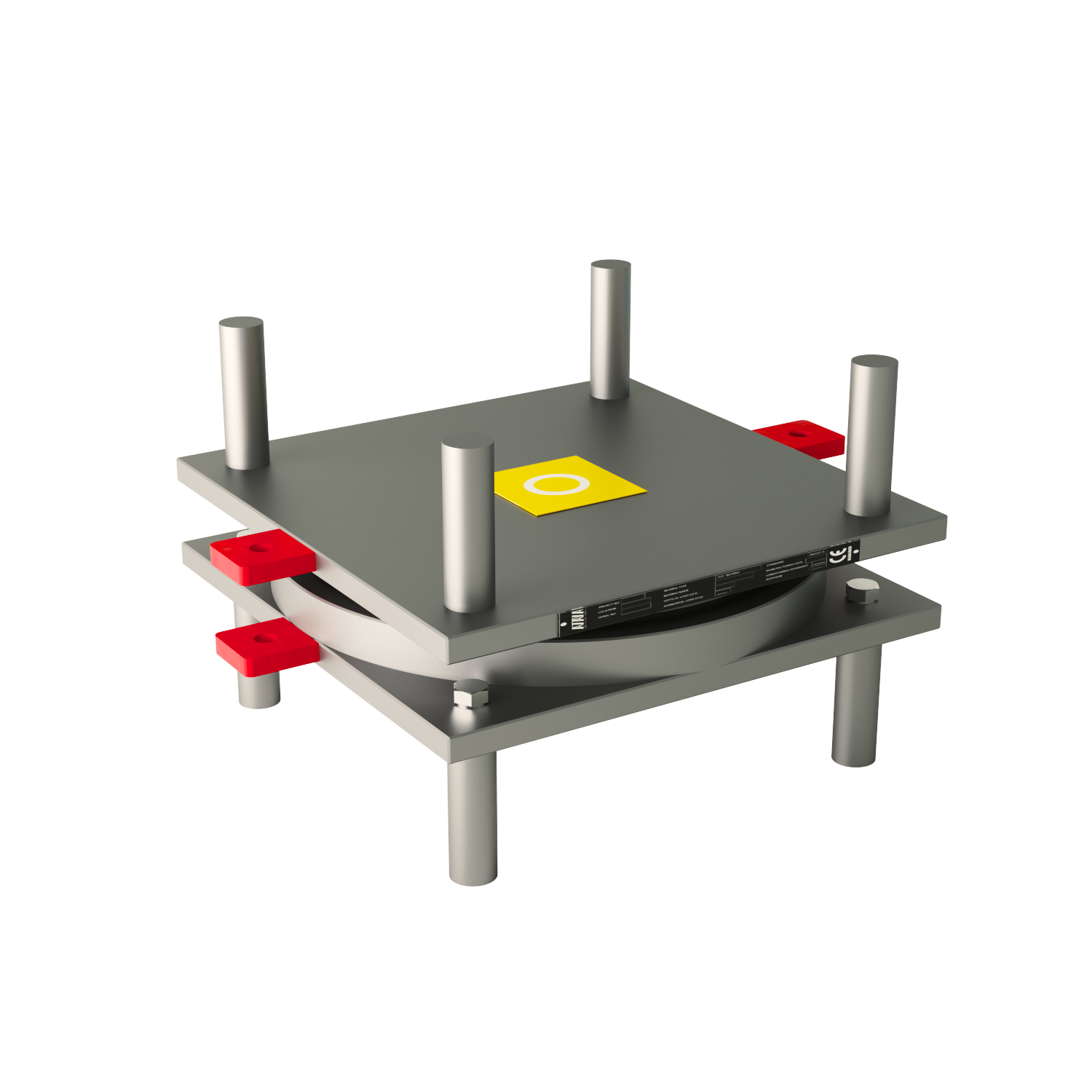

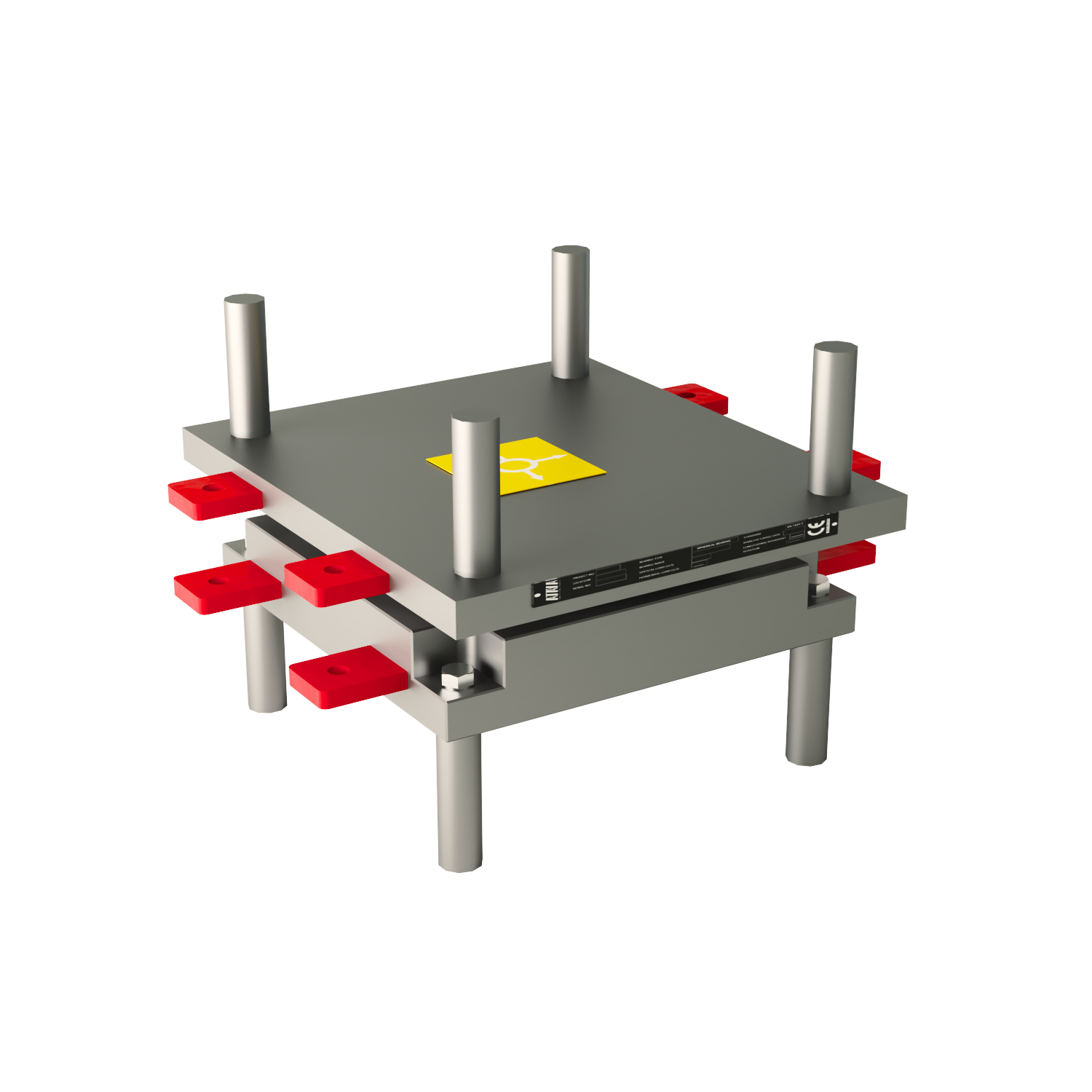

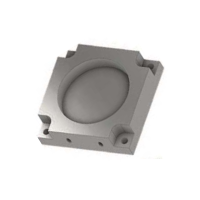

FIXED POT BEARING

This type of bearings restricts horizontal loads in longitudinal and transverse directions, therefore, does not allow any movement and consists of POT, piston assembly including an elastomeric pad which is encapsulated and fitted with

an anti-extrusion sealing ring under vertical load this encapsulated elastomeric

behaves like a viscous fluid, allowing rotations around the horizontal axis.

GUIDED POT BEARING

This type of bearings allows movement in one direction

between stainless steel and lubricated PTFE which

is placed on the piston and restricts horizontal loads

perpendicular to the direction of movement by a guide

bar placed in the center of the piston

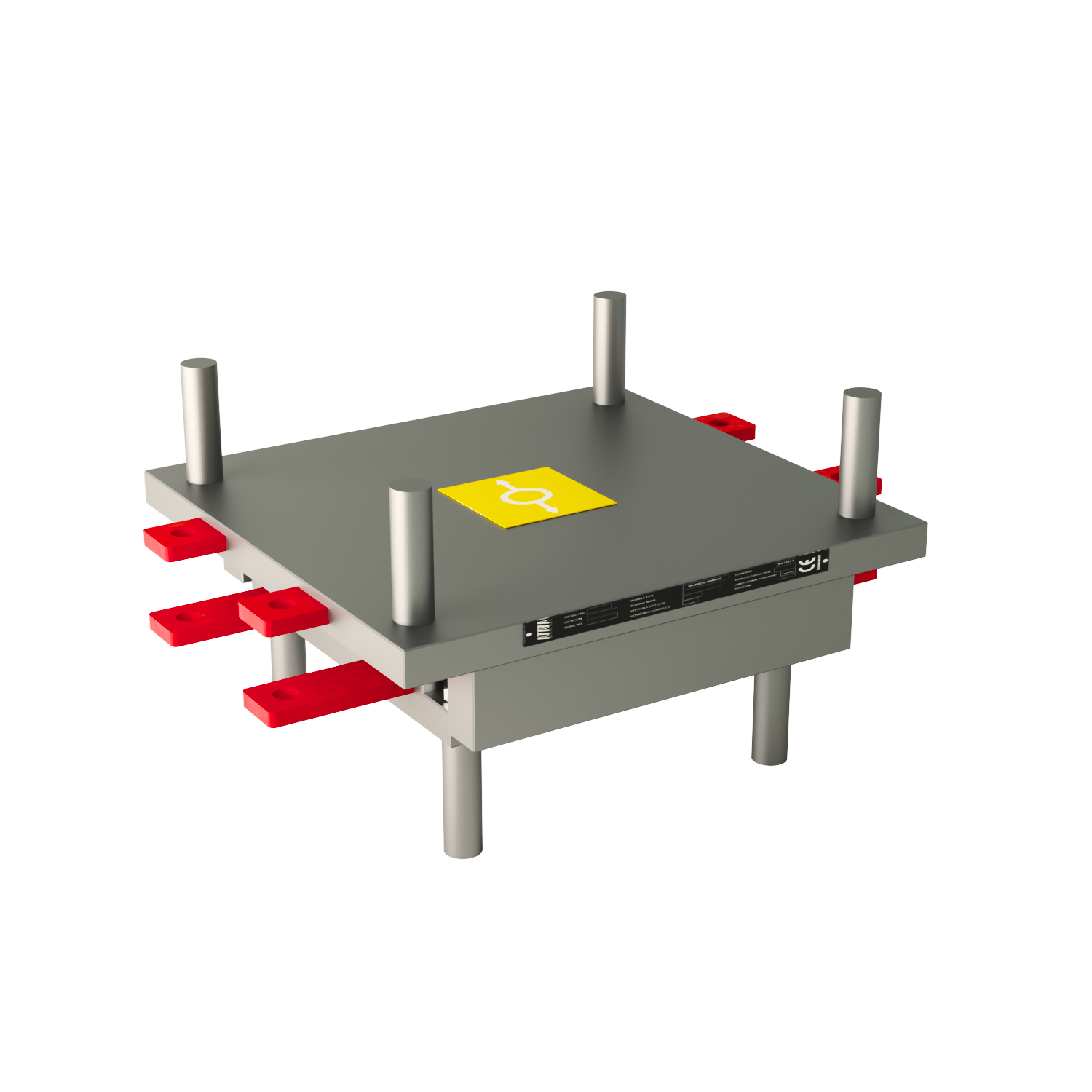

FREE SLIDING POT BEARING

This type of bearings allows movements in both longitudinal and transverse directions between stainless steel and lubricated PTFE which is placed on the Piston, therefore, does not restrict horizontal loads except for nominal friction.

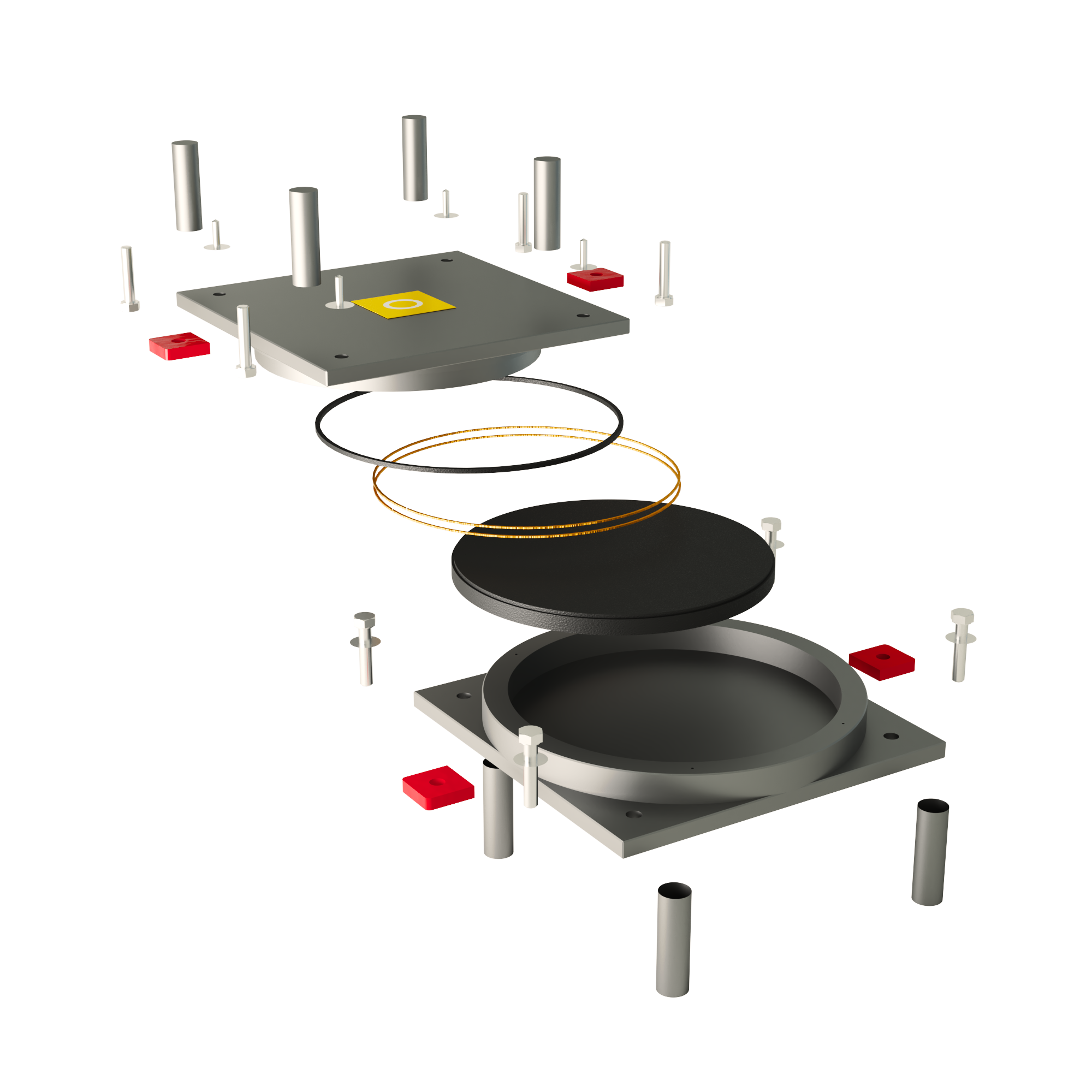

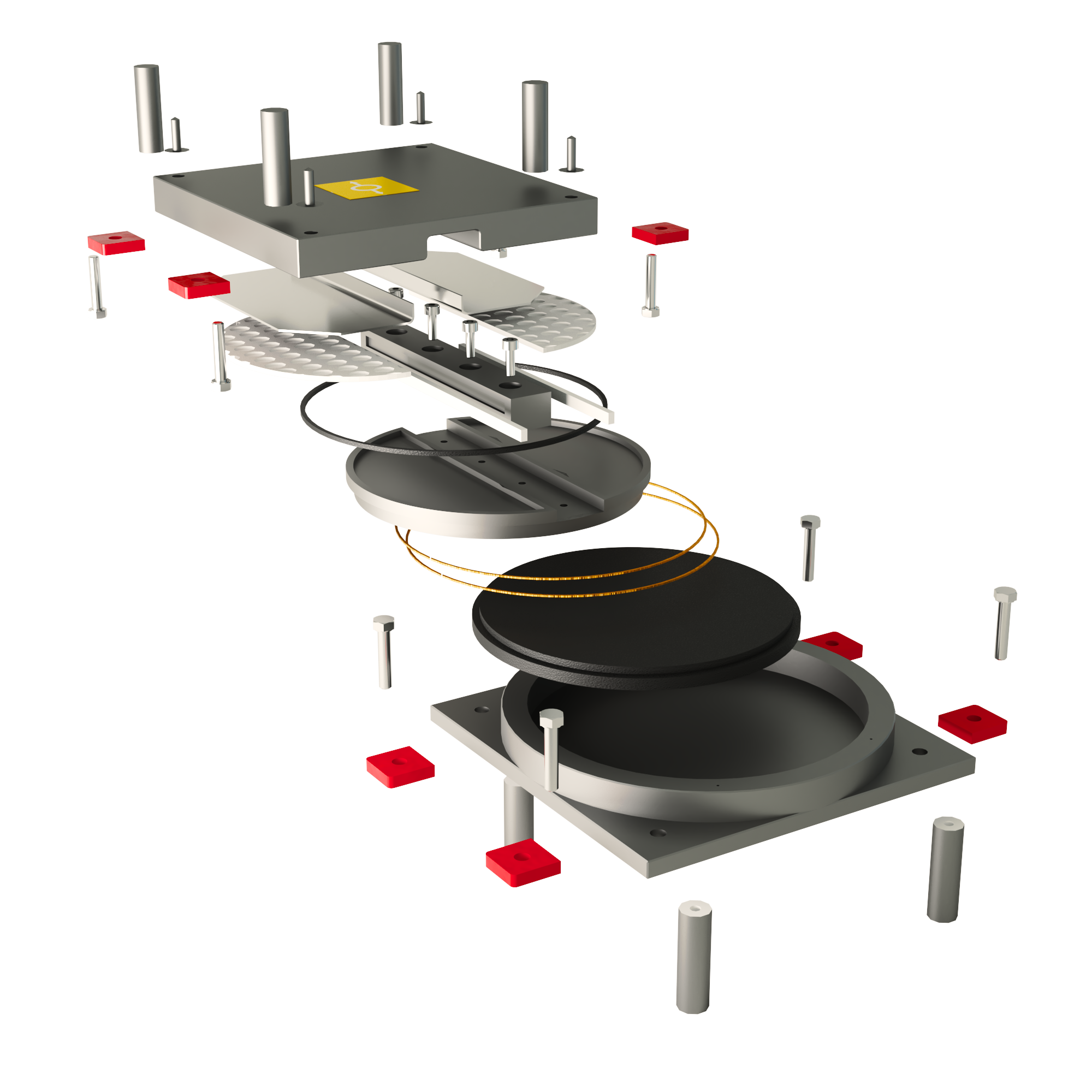

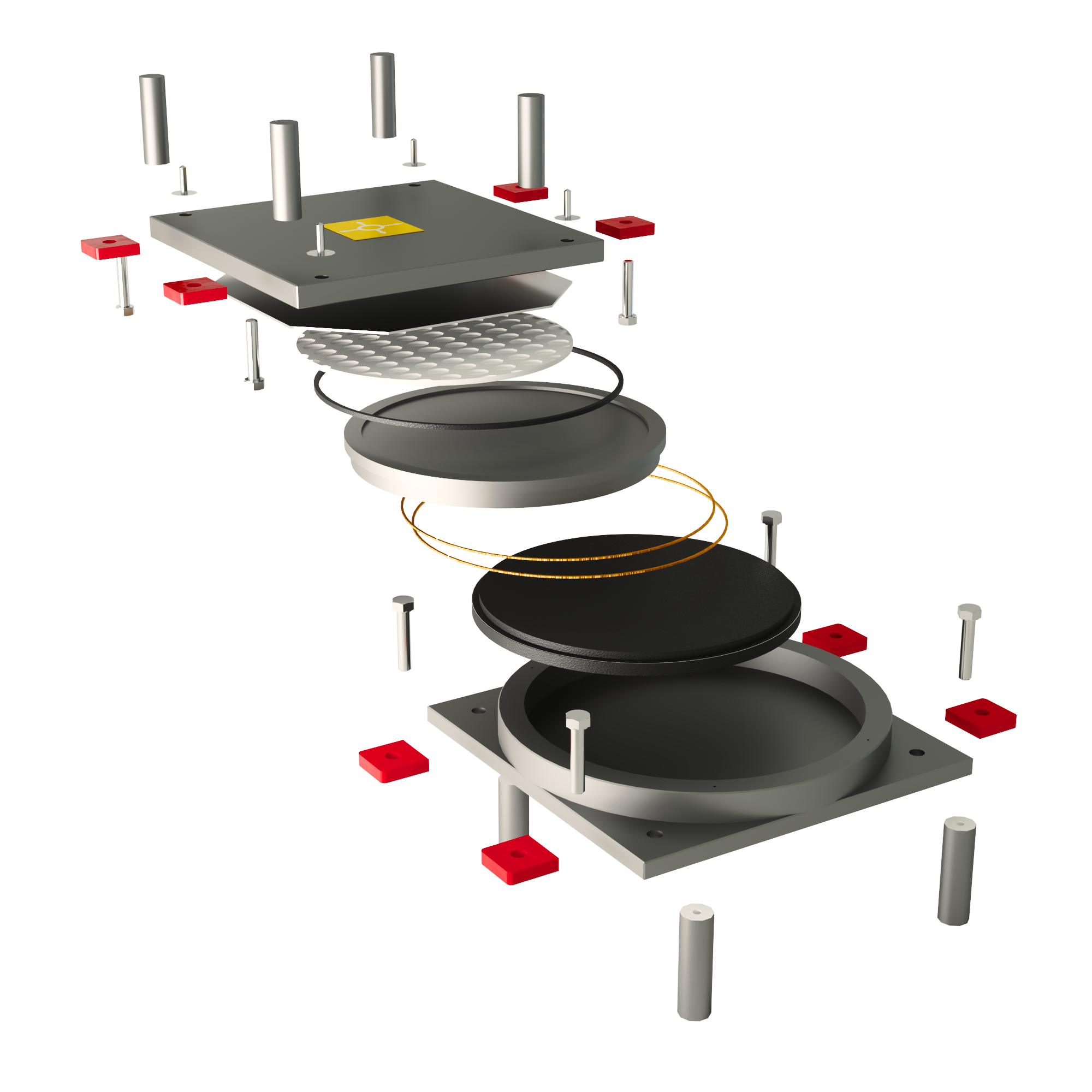

Bearings Components

PISTON

ELASTOMERIC PAD

EXTERNAL SEAL

POT

INTERNAL SEAL

ANCHORS & BOLT

mATERIAL SPECIFICATIONS

POT AND PISTON

The pot and piston shall be manufactured from ferrous materials according to EN 10025.

INTERNAL SEAL (BRASS SEAL)

Internal seals made from materials in annex A are in the scope of this standard En1337-5

1- Brass :

The material used for the brass seal shall be grade

CuZn37 or CuZn39Pb3, as specified in EN 12163

and EN 12164 respectively.

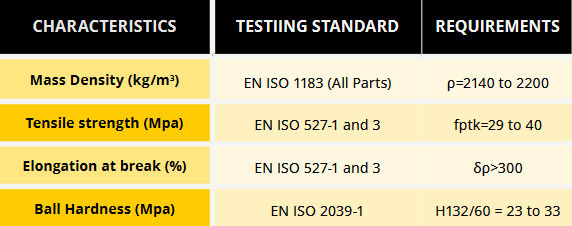

2- POM seal :

The material used for the moulded seals shall be

polyoxymethylene (POM) and shall have the

properties shown in Table A.2.

3- Carbon filled PTFE seal :

The material composition shall

consist of PTFE + 25 % carbon.

The material properties shall be in accordance with the

requirements of Table A.3 .

4-Stainless steel seal :

The material used for the stainless steel

seal shall be as specified in EN 10088-2, 1.4401 or 1.4311

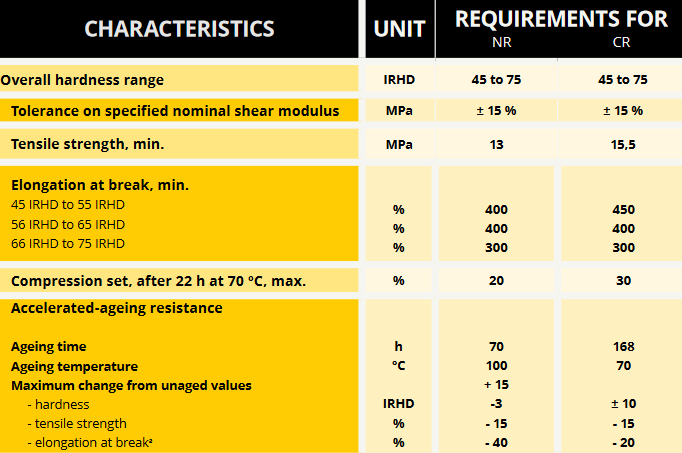

ELASTOMETRIC PAD

The elastomer material used for the elastomeric pad shall be natural or polychloroprene rubber in accordance with ISO 6446.

AUSTENITIC STEEL SHEETS

The austenitic steel used for sliding surfaces according to

EN 10088-2 1.4401 +2B with

minimum thickness of 1.5mm

The roughness is Ry5i < 1 μm according to EN ISO 4287.

The hardness ranges from (150HV1-220HV1) according to

EN ISO 6507-2.

SLIDING PLATE (PTFE)

The PTFE sheets shall be Pure polytetrafluorethylene free sintered without regenerated or filler materia.

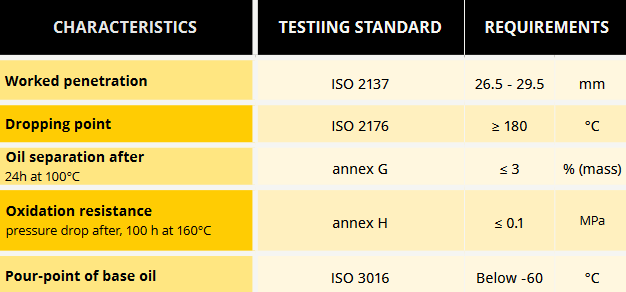

LUBRICANT (SILICONE GRESE)

The lubricant shall not be harmful to the elastomer or other

components and shall not cause excessive swelling of the elastomer.