The Ultimate Guide to Spherical Bearing Catalog: Design, Prices, and Applications

Spherical bearings are revolutionary components hidden in plain sight, driving the performance of countless machines and structures. This ultimate guide will navigate you through the spherical bearing catalog, revealing insights on design, pricing, and application that you won’t want to miss.

Introduction to Spherical Bearings

Spherical bearings, with their unique design, offer incredible flexibility and load-bearing capabilities. Understanding how they function is crucial, especially for industries seeking efficient spherical bearing assembly. These versatile components allow for misalignment, making them essential in various applications, from aerospace to construction. But what exactly makes a spherical bearing tick?

Exploring the Spherical Bearing Catalog

When looking through a spherical bearing catalog, you’ll find a plethora of options tailored for both standard and specialized needs. These catalogs guide engineers and buyers alike through:

- Size Variations: Spherical bearings come in various diameters and materials.

- Load Ratings: Each bearing is rated for specific load capacities; understanding these helps in proper selection.

- Design Features: Many feature integrated seals, enhanced lubrication, and material considerations.

Below is a sample comparison of common spherical bearing types:

| Type | Load Rating (kg) | Material | Typical Applications |

|---|---|---|---|

| Standard Spherical Bearing | 1500 | Steel | Heavy machinery |

| Spherical Air Bearing | 800 | Aluminum | Precision instruments |

Understanding Spherical Bearing Prices

Pricing for spherical bearings can vary significantly. Factors that influence spherical bearing price include:

- Material: Premium materials often come at a higher cost.

- Size and Capacity: Larger bearings or those with higher load capacities usually have higher prices.

- Manufacturing Technique: Custom-made bearings often require specialized processes, affecting the price.

On average, you can expect to pay anywhere from $10 to $500 depending on these factors. Always remember to assess the long-term value over upfront costs.

Key Components of Spherical Bearing Assembly

The spherical bearing assembly comprises multiple critical components. A typical assembly includes:

- Outer Sphere: Provides a bearing surface that allows for rotation.

- Inner Ring: Often incorporates an attachment for the shaft.

- Seal: Protects against contamination and retains lubrication.

Correct assembly is crucial; improper installation may lead to premature failure and costly repairs.

Applications of Spherical Air Bearings

Spherical air bearings utilize a thin film of air for frictionless motion, ideal for high-precision environments. Applications include:

- Medical devices where precision is critical.

- Aerospace components requiring minimal vibrations.

- Robotic systems for enhanced agility.

By utilizing these bearings, companies can significantly improve performance while reducing wear and tear.

Innovative Designs in Spherical Bearings

As technology advances, so does the design of spherical bearings. Recent innovations have led to:

- Self-Lubricating Materials: Reducing maintenance needs.

- Improved Load Distribution: Enhancing durability and lifespan.

- Customizable Designs: Catering to specific industrial needs.

These innovations are paving the way for more efficient, high-performing bearing solutions.

Preventing Spherical Bearing Failure

Spherical bearing failure can occur due to several issues, including poor lubrication, misalignment, and contamination. To prevent these failures:

- Regularly inspect bearings for wear and damage.

- Ensure proper alignment during installation.

- Implement effective dust and moisture protection.

By adhering to these guidelines, you can extend the lifespan of your bearings and maintain peak efficiency.

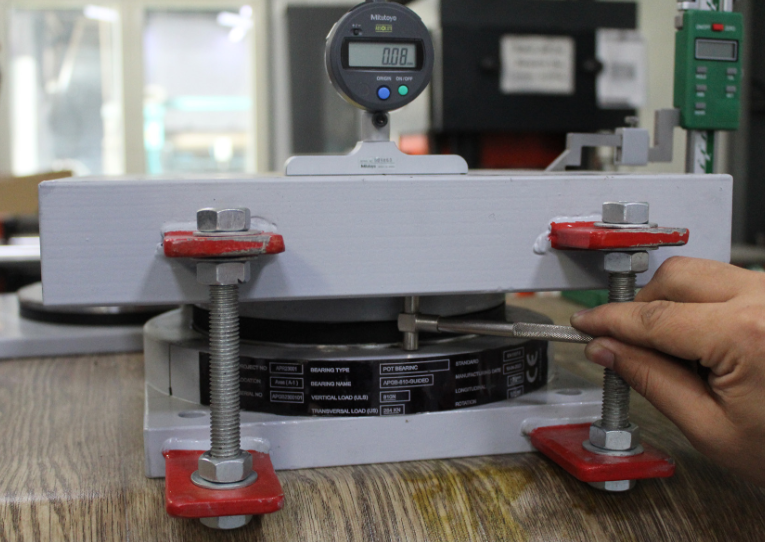

The Role of Spherical Bearings in Bridge Engineering

Spherical bearings play a pivotal role in bridge engineering. They allow for:

- Movement: Facilitating the expansion and contraction of bridge materials.

- Load Distribution: Supporting the weight of traffic and structural loads.

- Durability: Ensuring that bridges can withstand environmental stresses.

These bearings are crucial in maintaining structural integrity and ensuring safety.

Conclusion: The Future of Spherical Bearings

In summary, the spherical bearing catalog is more than just a list; it represents a technology vital to diverse industries. With continuous innovations in design and materials, the future of spherical bearings looks promising. To stay ahead in your field, consider the applications and maintenance of spherical bearings as part of your strategy.

For more insights into bearing technology and solutions, feel free to contact us, or explore our related articles for deeper discussions on industrial applications.

Stay informed, stay innovative!