Tapered bearings are the hidden heroes of engineering, silently ensuring that bridges and machinery function seamlessly. Understanding these crucial components not only elevates infrastructure projects but also enhances performance metrics, making the mastery of tapered bearings a necessity for every engineer and infrastructure firm.

Understanding Tapered Bearings: The Basics

What is a Tapered Bearing?

Is a type of rolling-element bearing that uses tapered rollers, which are cone-shaped. This design allows for a larger load capacity and improved performance over traditional bearings. They excel in various applications, particularly where axial and radial loads are present simultaneously.

Key Components of the Bearings

- Outer Race: The external ring that houses the tapered rollers.

- Inner Race: The inner component, in which the roller elements rotate.

- Tapered Rollers: These are the elements that facilitate the movement and load distribution.

- Cage: The structure that holds the rollers in place, allowing for free rotation while maintaining spacing.

Tapered Bearing Sizes: Exploring the Size Chart

How to Choose the Right Size

Choosing the right size is paramount to ensure optimal performance and longevity. Refer to the tapered bearing size chart for assistance in making your selection. Consider these factors:

- Load Capacity: Evaluate the types of loads the bearing will encounter.

- Dimensional Constraints: Ensure the selected bearing fits within the designated space.

- Operating Conditions: Consider temperature, humidity, and exposure to contaminants.

Tapered Bearing vs Spherical Roller Bearing: A Comparative Analysis

Performance Characteristics of Tapered Roller Bearings

Tapered roller bearings offer distinct advantages over spherical roller bearings in specific applications:

- Load Distribution: They distribute loads better due to their shape, which is beneficial in dynamic applications.

- Axial and Radial Load Handling: They are adept at accommodating both axial and radial loads, making them versatile.

Applications and Limitations

While tapered roller bearings are widely used in various industries, including automotive and construction, they are not without limitations:

- Advantages:

- High load capacity

- Reduced friction

- Durability in demanding conditions

- Limitations:

- More sensitive to alignment issues

- Requires precise preload adjustments

The Preload: Understanding Its Importance

Effects of Incorrect Preload on Performance

Preload is the initial load applied to a bearing, which ensures that the components are properly aligned. Incorrect preload can lead to:

- Increased wear and tear

- Higher friction leading to overheating

- Reduced lifespan of the bearing

The Role in Bridge Construction

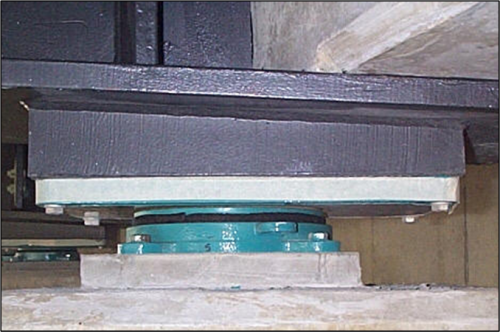

Bridge Bearings: Why Tapered Bearings Are Preferred

They are indispensable in bridge construction due to their unique capabilities:

- Load Support: They provide excellent resistance against loads, enhancing structural integrity.

- Movement Accommodation: They allow for controlled movements caused by thermal expansion and contraction.

Real-World Applications in Infrastructure Development

From pedestrian walkways to heavy-duty vehicular bridges, tapered bearings play a pivotal role in various infrastructure projects, ensuring safety and longevity.

Maintenance Tips

Common Issues and Solutions

Proper maintenance is critical for their performance. Here are some common issues and their solutions:

- Issue: Overheating

Solution: Ensure proper lubrication and check the preload settings. - Issue: Excessive wear

Solution: Inspect alignment and replace damaged components.

Best Practices for Longevity

To extend the life of the bearings, consider the following practices:

- Regular inspections for wear and tear

- Maintaining optimal lubrication levels

- Employing appropriate preload settings

Conclusion

Tapered bearings are a crucial component in various applications, especially within infrastructure projects like bridges. Understanding their specifications, advantages, and maintenance can significantly enhance performance and longevity. For engineers and infrastructure firms, mastering the intricacies of tapered bearings equates to safety, durability, and efficiency.

If you want to delve deeper into tapered bearing solutions or seek professional advice, contact us today! Together, we can build a stronger future.